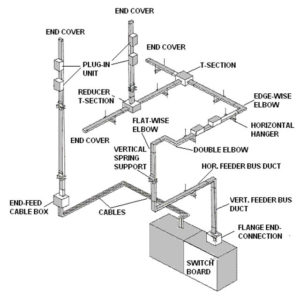

Busducts in any electrical construction, are usedfor transporting electrical power...

Read MoreFacilities Support Services

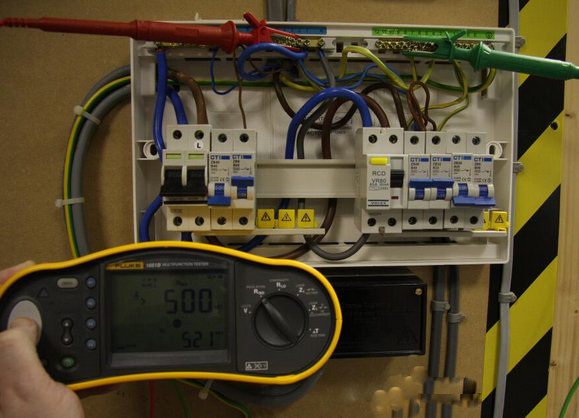

insulation resistance test

Insulation Resistance Test

Insulation starts to age as soon as it’s made. As it ages, its insulating performance deteriorates. Any harsh installation environments, especially those with temperature extremes and/or chemical contamination, accelerates this process. This deterioration can result in dangerous conditions in power reliability and personnel safety. As such, it’s important to identify this deterioration quickly so that corrective steps can be taken. One of the simplest tests and its required test instrument are not universally understood. To help eliminate this lack of understanding, let’s discuss in detail Insulation Resistance (IR) testing and the megohmmeter.

1) Insulation resistance (IR)

This is the simplest of the tests. After the required connections are made, you apply the test voltage for a period of one min. (The one-min interval is an industry practice that allows everyone to take the reading at the same time. In this way, comparison of readings will be of value because, although taken by different people, the test methods are consistent.) During this interval, the resistance should drop or remain relatively steady. Larger insulation systems will show a steady decrease, while smaller systems will remain steady because the capacitive and absorption currents drop to zero faster on smaller insulation systems. After one min, read and record the resistance value.

2) Dielectric absorption ratio

This test recognizes the fact that “good” insulation will show a gradually increasing IR after the test voltage is applied. After the connections are made, the test voltage is applied, and the IR is read at two different times: Usually either 30 and 60 sec, or 60 sec and 10 min. The later reading is divided by the earlier reading, the result being the dielectric absorption ratio. The 10 min./60 sec. ratio is called the polarization index (PI).

3) Step voltage test

This test is particularly useful in evaluating aged or damaged insulation not necessarily having moisture or contamination. A dual voltage test instrument is required here. After the connections are made, the IR test is done at a low voltage, say 500V. The test specimen then is discharged and the test is done again, this time at a higher voltage, say 2500V. If more than a 25% difference exists between the two IR readings, age deterioration or damaged insulation should be suspected.

Related Post

Air Circuit Breaker (ACB) : Construction, Operation, Types & Applications

Table of Contents What is a Circuit Breaker?Air Circuit BreakerConstruction...

Read MoreLV-Switchgear Service / Maintenance / AMC

Electrical distribution and control systems are the heart of any...

Read MoreWe Make The Most Of Your Power

TPTS is a team of enthusiastic individuals who has executed many prestigious projects in various market segments .

In Technical Association with

© 2019-20 Three Phase Technical Services LLC. All Rights Reserved.