Power System Study & Analysis

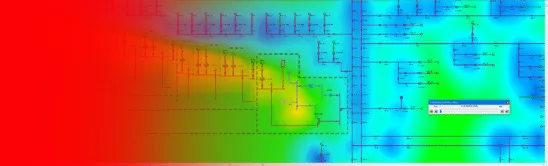

Electrical system design, expansion, and safe operation require detailed engineering analysis to verify equipment ratings, optimize performance, and ensure personnel safety. Three Phase Tech Services delivers comprehensive power system studies using industry-standard software including ETAP and other leading platforms. Facility managers, consulting engineers, and project teams rely on these studies for system design validation, regulatory compliance, and operational optimization.

Why This Service Matters

Power system studies form the engineering foundation for electrical infrastructure decisions. Without proper analysis, facilities risk undersized equipment, protection failures, safety hazards, and operational inefficiencies that can lead to costly outages and accidents.

Problems Addressed

- Uncertainty about equipment ratings and fault withstand capability

- Protective devices that fail to coordinate properly during faults

- Voltage problems affecting motor starting and equipment operation

- Arc flash hazards without documented safety boundaries

- Harmonic distortion causing equipment overheating and failures

- Inadequate grounding systems creating safety risks

- System expansion without validated capacity analysis

Potential Outcomes

- Verified equipment ratings against calculated fault currents

- Coordinated protection that isolates faults with minimum system disruption

- Optimized voltage profiles across all operating conditions

- Documented arc flash hazard levels and PPE requirements

- Harmonic mitigation strategies for power quality compliance

- Safe and effective grounding system design

- Engineering documentation supporting design and operational decisions

Power Study using ETAP & Other Leading Software

Specialized studies address different aspects of electrical system analysis. Each study can be conducted independently or combined into a comprehensive power system evaluation.

Comprehensive electrical system analysis combining multiple study types to evaluate system performance, protection adequacy, and equipment ratings across all operating conditions.

Steady-state analysis determining voltage levels, power flows, and equipment loading throughout the electrical system under various operating scenarios.

Fault current calculations determining maximum and minimum short circuit currents at all system locations for equipment rating verification and protection coordination.

Time-current coordination analysis ensuring protective devices operate in proper sequence to isolate faults with minimum system disruption.

Incident energy calculations and protection boundary determination for electrical safety compliance with NFPA 70E and OSHA requirements.

Frequency domain analysis evaluating harmonic distortion levels, identifying sources, and developing mitigation strategies for IEEE 519 compliance.

Comprehensive electrical system analysis combining multiple study types to evaluate system performance, protection adequacy, and equipment ratings across all operating conditions.

Earthing, Grounding Study & Analysis

Analysis and design of grounding systems including ground grid sizing, step and touch potential calculations, and grounding system adequacy verification.

Calculation of voltage levels throughout the distribution system under various loading conditions to verify adequate voltage at equipment terminals.

Dynamic simulation of motor starting events to evaluate voltage dip, acceleration time, and system stability during motor starting sequences.

Segments We Serve

Retail

Healthcare

Hospitality

data centers

Manufacturing

Processing Industry

Facility Management

Water Treatment Plants

Study Applications

New Installation Design

- Equipment sizing and selection validation

- Protection scheme design and relay settings

- Cable sizing verification

- Transformer tap position optimization

- Switchgear rating confirmation

- Grounding system design

Existing System Evaluation

- Capacity assessment for expansion planning

- Protection coordination verification

- Arc flash hazard assessment

- Power quality evaluation

- Equipment rating adequacy review

- Grounding system adequacy verification

System Modification

- Load addition impact analysis

- Generator interconnection studies

- Utility service upgrade evaluation

- Protection setting updates

- Single line diagram updates

Compliance and Safety

- Arc flash labeling program support

- Electrical safety program documentation

- Insurance requirement compliance

- Regulatory submission support

- Third-party review documentation

Technical Reports

- Executive summary with key findings

- Study methodology and assumptions

- System modeling description

- Detailed calculation results

- Equipment evaluation tables

- Recommendations with supporting analysis

Engineering Drawings

- Updated single line diagrams

- Protection coordination curves

- Arc flash labels

- Equipment rating summaries

- Grounding system layouts

How Engagement Works

Three engagement models accommodate different project requirements.

Duration: 2 to 6 weeks depending on system size

Duration: 4 to 12 weeks depending on scope

Frequency: As required with priority response

Applicable Standards

Power system studies follow applicable IEEE, IEC, and NFPA standards:

IEEE Standards

- IEEE 141 (Red Book) – Electric Power Distribution for Industrial Plants

- IEEE 242 (Buff Book) – Protection and Coordination

- IEEE 399 (Brown Book) – Power Systems Analysis

- IEEE 493 (Gold Book) – Reliability

- IEEE 551 (Violet Book) – Short Circuit Calculations

- IEEE 1584 – Arc Flash Hazard Calculations

- IEEE 519 – Harmonic Control

- IEEE 80 – Guide for Safety in AC Substation Grounding

- IEEE 142 (Green Book) – Grounding of Industrial and Commercial Power Systems

IEC Standards

- IEC 60909 – Short Circuit Currents

- IEC 61000 – Electromagnetic Compatibility (Harmonics)

- IEC 60076 – Power Transformers

- IEC 62271 – High Voltage Switchgear

Safety Standards

- NFPA 70E – Electrical Safety in the Workplace

- OSHA 1910.269 – Electric Power Generation

- OSHA 1910.303 – Electrical Installation Requirements

Frequently Asked Questions

What information is needed to perform a power system study?

Studies require single line diagrams, equipment nameplate data, cable schedules, transformer test reports, utility fault current data, and protection device settings. Additional information depends on specific study requirements.

How long does a power system study take?

Duration depends on system size and study scope. Individual studies for small systems may complete in 2 to 3 weeks. Comprehensive studies for large industrial facilities may require 8 to 12 weeks.

How often should power system studies be updated?

Studies should be updated when significant system changes occur including load additions, equipment replacements, utility service modifications, or protection device changes. Arc flash studies typically require updating every 5 years or after system modifications.

What is the difference between load flow and short circuit studies?

Load flow analysis evaluates normal operating conditions including voltage levels and power flows. Short circuit analysis calculates fault currents for equipment rating verification and protection coordination.

Can studies be performed on existing systems without shutting down?

Data collection for existing systems can largely be performed during normal operation. Nameplate data collection and single line diagram verification may require access to equipment during scheduled maintenance windows.

What software do you use for power system studies?

Primary analysis uses ETAP, which is an industry-standard platform for comprehensive power system studies. SKM Power Tools and other platforms are used based on project requirements and client specifications.

Do you provide relay settings or just recommendations?

Studies provide recommended relay settings based on coordination analysis. Implementation of settings can be performed as a separate service or by client personnel using study recommendations.

Why is grounding study important?

Grounding studies ensure personnel safety by verifying step and touch potentials remain within safe limits during fault conditions. Proper grounding also ensures effective fault current dissipation and protection system operation.