Electrical Services, Testing & Modernization Solutions

Aging electrical infrastructure, capacity constraints, and evolving safety standards demand ongoing attention from facility operators. Three Phase Tech Services delivers comprehensive electrical services covering switchgear maintenance, equipment testing, retrofit solutions, and system modernization. Facility managers, maintenance engineers, and plant operations teams rely on these services to maintain equipment reliability, extend asset life, and ensure regulatory compliance.

Why This Service Matters

Electrical distribution systems require regular testing, maintenance, and periodic upgrades to perform safely and reliably. Equipment that operates beyond its service life or without proper maintenance poses risks including unplanned outages, safety hazards, and costly emergency repairs.

Problems Addressed

- Aging switchgear with obsolete components and limited spare parts availability

- Circuit breakers that have not been tested or maintained in years

- Capacitor bank failures due to harmonic stress or deterioration

- VFD malfunctions affecting motor performance and process control

- Lack of documented maintenance records for insurance and compliance

- Delayed commissioning causing project schedule overruns

Potential Outcomes

- Extended equipment service life through proper maintenance and upgrades

- Reduced risk of unplanned outages and equipment failures

- Improved system reliability and operational continuity

- Compliance with electrical safety codes and insurance requirements

- Modern protection and control features on existing infrastructure

- Documented maintenance history for asset management

Electrical Services, Testing & Modernization Solutions

Specialized services address different aspects of electrical system maintenance, testing, and modernization. Each service can be delivered independently or as part of a comprehensive maintenance program.

LV/MV

Switchgear

Service

Preventive maintenance, testing, and annual maintenance contracts for low tension and high tension switchgear including panels, circuit breakers, busbars, and protection systems.

LV & MV

Retrofit

Solutions

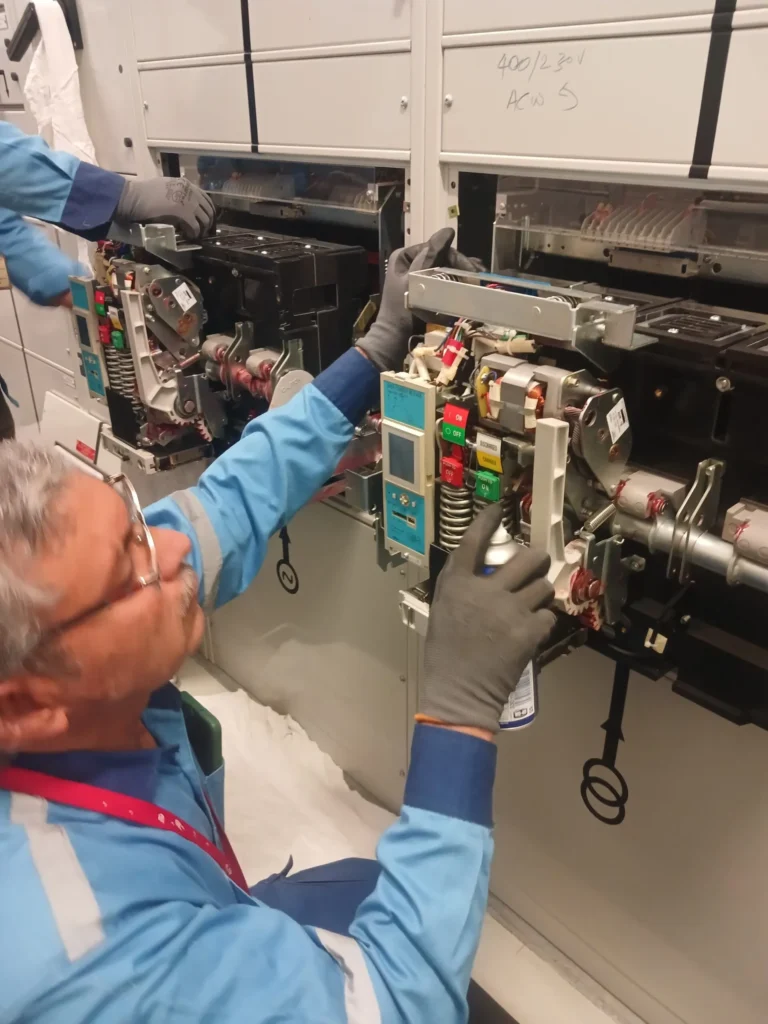

Upgrade and modernization of existing air circuit breakers, molded case circuit breakers, and switchgear assemblies to restore protection capability and extend operational life.

Capacitor Bank Service & Maintenance

Installation, commissioning, and maintenance of power factor correction capacitor banks including reactive power compensation systems with detuned reactors.

VFD & Controlgear: Retrofit

Installation, programming, and commissioning of variable frequency drives for motor speed control applications across industrial processes.

3rd Party Inspection & Testing

Pre-commissioning testing, functional verification, and energization support for new electrical installations and equipment replacements.

Segments We Serve

Retail

Healthcare

Hospitality

data centers

Manufacturing

Processing Industry

Facility Management

Water Treatment Plants

Service Capabilities & Equipment Covered

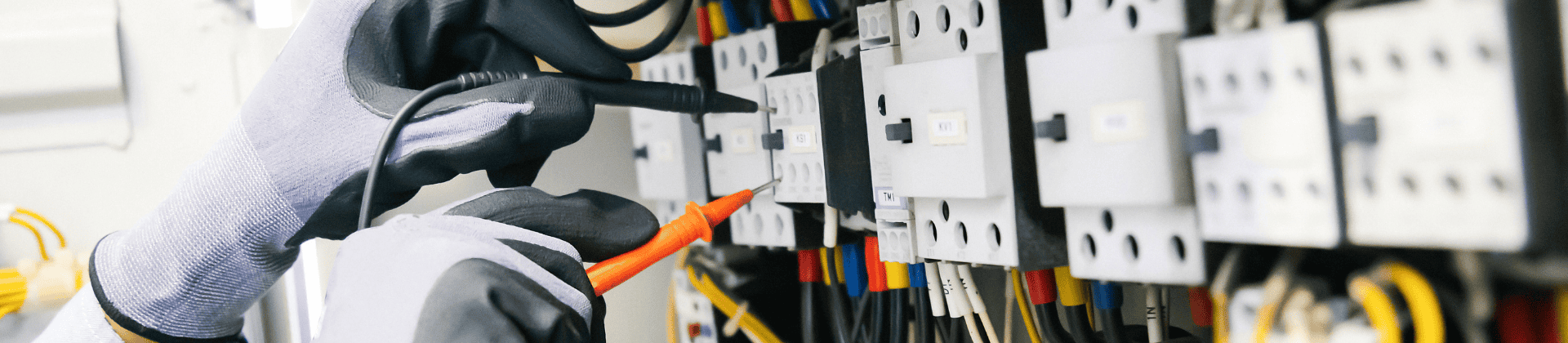

Switchgear Testing

- Insulation resistance testing using calibrated meggers

- Contact resistance measurement

- High potential (hipot) testing

- Circuit breaker timing tests

- Protection relay testing and calibration

- Functional operation verification

Preventive Maintenance

- Visual inspection and cleaning

- Connection torque verification

- Lubrication of operating mechanisms

- Arc chute inspection and replacement

- Contact wear assessment

- Thermal imaging of energized equipment

Retrofit and Modernization

- Direct replacement retrofit kits for obsolete breakers

- Retrofill solutions using modern breakers in existing cubicles

- Protection relay upgrades from electromechanical to digital

- Metering system modernization

- Control circuit modifications

Commissioning Support

- Factory acceptance test witnessing

- Site acceptance testing

- Protection coordination verification

- Functional testing of interlocks and safety systems

- Energization procedures and supervision

Equipment Covered

- Air circuit breakers (ACB) from all major manufacturers

- Molded case circuit breakers (MCCB)

- Vacuum circuit breakers (VCB)

- SF6 circuit breakers

- Low tension panels and distribution boards

Manufacturer Coverage

- Schneider Electric & ABB

- Siemens & L&T

- Havells & Legrand

- Eaton

- GE & Crompton Greaves

- BHEL

How Engagement Works

Three service delivery models accommodate different facility requirements.

Response: Based on availability and urgency

Frequency: Monthly, quarterly, or semi-annual

Duration: 12-month contracts with renewal options

Applicable Standards

All testing and maintenance activities reference applicable standards:

- IS 13947 (Low Voltage Switchgear and Controlgear)

- IS 3427 (Metal-Enclosed Switchgear)

- IEC 62271 (High Voltage Switchgear)

- IEC 61439 (Low Voltage Switchgear Assemblies)

- NETA MTS (Maintenance Testing Specifications)

- NFPA 70B (Recommended Practice for Electrical Equipment Maintenance)

- IEEE C37 series (Switchgear Standards)

- IE Rules 1956/2003

Frequently Asked Questions

How often should switchgear be tested?

Testing frequency depends on equipment criticality, operating environment, and load conditions. General guidelines suggest annual inspection with detailed testing every 3 to 5 years. High-criticality equipment may require more frequent testing.

What is included in a switchgear AMC?

Annual maintenance contracts typically include scheduled preventive maintenance visits, electrical testing, minor repairs, priority emergency response, and detailed maintenance reports. Scope is customized based on equipment inventory and facility requirements.

Common symptoms include equipment overheating, nuisance tripping of circuit breakers, transformer humming, capacitor failures, motor vibration, and unexplained equipment malfunctions. Power quality analysis can identify and quantify specific issues.

Can obsolete circuit breakers be replaced without changing the entire panel?

Yes. Retrofit solutions allow installation of modern circuit breakers in existing switchgear cubicles. Direct replacement kits and retrofill options are available for most major brands, avoiding the cost and disruption of complete panel replacement.

What is the difference between retrofit and retrofill?

Retrofit involves replacing an obsolete breaker with a new breaker designed as a direct replacement for the original. Retrofill involves adapting a modern breaker to fit in an existing cubicle originally designed for a different breaker type.

Do you provide emergency breakdown service?

Yes. Emergency response is available for critical failures. AMC customers receive priority response. Emergency services include fault diagnosis, temporary repairs, and expedited parts procurement.

What documentation is provided after maintenance?

Maintenance reports include test results, photographs, condition assessment, findings summary, and recommendations. Reports support compliance documentation, insurance requirements, and asset management records.

Can testing be done without shutting down the facility?

Some tests require equipment to be de-energized for safety. Scheduling and phased approaches minimize operational impact. Thermal imaging and some diagnostic tests can be performed on energized equipment.

What qualifications do your technicians have?

Service technicians are trained on equipment from major manufacturers and follow established testing procedures. Team includes engineers with relevant certifications for electrical testing and safety.