Is Manual Temperature Checking Enough?

Relying only on manual checks increases the risk of missed faults and unexpected downtime. With DAVAS® real-time temperature monitoring and control, you receive instant alerts on abnormal temperature shifts, enabling fast response and asset protection.

Professional temperature monitoring and control systems provide comprehensive thermal management solutions for industrial processes, equipment protection, and quality control applications. Advanced temperature monitoring utilizes precision sensors, automated control algorithms, and real-time analytics to ensure optimal thermal conditions and prevent temperature-related failures.

Limitations of traditional temperature checking:

- Handheld measurements with limited coverage

- Fragile wired sensors prone to failure

- Hidden risks that cause sudden breakdowns

- Time-intensive monitoring routines

- Inconsistent readings, delays, and complicated data collection

Send Enquiry

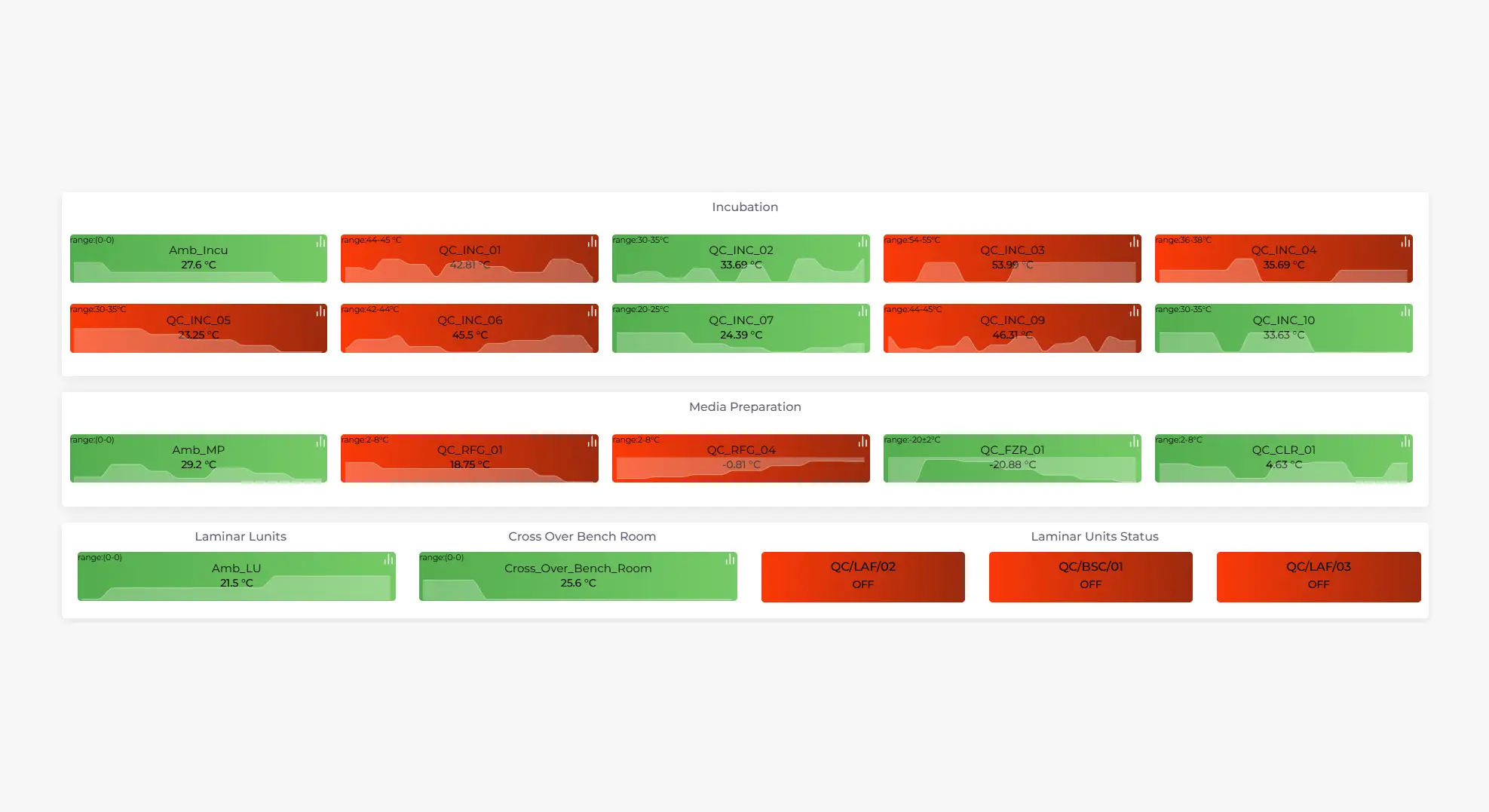

DAVAS® Temperature Monitoring Solution

Stay ahead of Temperature changes and ensure your equipment operates at peak efficiency.

DAVAS® Temperature Monitoring Solution provides comprehensive thermal management capabilities including real-time temperature measurement, automated control, alarm management, and data analytics. The platform integrates multiple sensor technologies with advanced control algorithms ensuring optimal thermal conditions and equipment protection.

Stay ahead of Temperature changes and ensure your equipment operates at peak efficiency.

Benefits

Smarter Maintenance Planning

Identifies and resolves problems before they grow, reducing downtime and extending asset life. Intelligent maintenance planning through predictive temperature analysis, trend monitoring, and early fault detection. Smart maintenance capabilities optimize maintenance schedules based on actual thermal conditions rather than fixed intervals.

Early Fault Detection

Spots overheating, imbalance, and other critical risks before they escalate into costly failures. Advanced fault detection algorithms identify developing thermal problems through pattern recognition, anomaly detection, and predictive analytics. Early detection enables proactive intervention preventing equipment damage and production losses.

Extended Equipment Life

Addresses lubrication issues that directly impact machinery durability. Equipment life extension through optimal thermal management, lubrication monitoring, and overheating prevention. Thermal optimization reduces thermal stress and material degradation extending equipment operational life.

Continuous Operations

Prevents sudden halts by monitoring bearings and other sensitive points. Continuous operation assurance through comprehensive thermal monitoring, automated control, and immediate response to thermal excursions. Continuous monitoring prevents unexpected shutdowns and production interruptions.

Energy Savings

Minimizes motor overheating and reduces wasted energy. Energy efficiency optimization through thermal management, overheating prevention, and optimal operating temperature maintenance. Energy savings result from improved efficiency and reduced cooling requirements.

Operational Efficiency

Boosts reliability, reduces costs, and improves asset performance with proactive fault detection. Overall operational efficiency improvement through comprehensive thermal management, automated optimization, and proactive maintenance. Efficiency gains include improved reliability, reduced costs, and enhanced productivity.

Temperature Monitoring Solutions

Frequently Asked Questions

What is temperature monitoring and control?

Temperature monitoring and control is a comprehensive system that continuously measures, tracks, and regulates temperature in industrial processes and equipment using precision sensors, automated control systems, and real-time analytics to ensure optimal performance and safety.

Temperature monitoring systems provide real-time temperature data, trend analysis, alarm management, and automated control enabling proactive thermal management and process optimization.

What types of temperature sensors are used?

Industrial temperature monitoring uses RTD sensors, thermocouples, thermistors, and infrared sensors. Sensor selection depends on temperature range, accuracy requirements, response time, and environmental conditions.

Multiple sensor types are often combined to provide comprehensive temperature monitoring coverage addressing different measurement requirements and environmental conditions.

How accurate are temperature monitoring systems?

Professional temperature monitoring systems achieve accuracy levels of ±0.1°C to ±1°C depending on sensor type and application requirements. RTD sensors provide the highest accuracy while thermocouples offer wide temperature ranges.

Accuracy is maintained through proper sensor selection, professional installation, regular calibration, and appropriate system design for specific applications.

What industries use temperature monitoring systems?

Temperature monitoring serves pharmaceutical, food processing, chemical, manufacturing, HVAC, data centers, and research industries requiring precise temperature control for product quality, safety, and regulatory compliance.

Each industry has specific temperature monitoring requirements addressing unique processes, safety standards, and regulatory compliance obligations.

How does wireless temperature monitoring work?

Wireless temperature monitoring uses battery-powered sensors transmitting data via LoRa, Wi-Fi, or cellular networks to central monitoring systems. Wireless systems provide installation flexibility and reduced infrastructure costs.

What is the difference between monitoring and control?

Temperature monitoring measures and tracks temperature data while temperature control actively regulates temperature through automated systems. Control systems use monitoring data to maintain desired temperature setpoints.

How often should temperature sensors be calibrated?

Calibration frequency depends on application requirements and regulatory standards. Typical calibration intervals range from 6 months to 2 years with critical applications requiring more frequent calibration.

Can temperature monitoring integrate with existing systems?

Yes, DAVAS® temperature monitoring integrates with building management systems, process control systems, and enterprise software through standard protocols including Modbus, BACnet, and Ethernet/IP.

Comprehensive Analysis of Traditional Temperature Monitoring Limitations

Traditional temperature monitoring methods face significant limitations including coverage gaps, measurement inconsistencies, response delays, and maintenance challenges. Manual temperature checking and basic monitoring systems cannot provide the comprehensive thermal oversight required for modern industrial operations.

Manual Measurement Challenges

Manual temperature measurements using handheld devices provide limited coverage, introduce human error, and cannot detect rapid temperature changes. Manual methods are labor-intensive, inconsistent, and inadequate for continuous monitoring requirements.

Manual Method Limitations

- Coverage Limitations: Limited measurement points and infrequent sampling intervals

- Human Error: Measurement inconsistencies and operator variability

- Response Delays: Delayed detection of temperature excursions and trends

- Safety Risks: Personnel exposure to hazardous environments for measurements

- Labor Intensive: High labor costs and resource requirements for monitoring

Wired Sensor Limitations

Traditional wired temperature sensors face installation challenges, maintenance issues, and reliability problems including cable failures, connection degradation, and environmental damage. Wired systems require extensive infrastructure and ongoing maintenance.

Wired System Challenges

- Installation Complexity: Extensive cabling and conduit installation requirements

- Cable Failures: Wire damage from environmental conditions and mechanical stress

- Maintenance Issues: Connector corrosion and connection degradation

- Scalability Problems: Difficult and expensive system expansion

- Single Points of Failure: Cable damage affecting multiple measurement points

Hidden Risk Factors

Traditional monitoring methods cannot detect developing thermal issues, intermittent problems, and gradual degradation patterns that lead to unexpected failures. Hidden risks accumulate over time creating catastrophic failure potential.

Undetected Risk Categories

- Gradual Degradation: Slowly developing thermal issues not detected by periodic checks

- Intermittent Problems: Temperature excursions occurring between manual measurements

- Thermal Cycling: Repeated heating and cooling cycles causing material fatigue

- Hot Spots: Localized overheating not detected by point measurements

- Process Variations: Temperature variations affecting product quality and consistency

Advanced Temperature Measurement Technologies

DAVAS® platform supports multiple temperature sensor technologies providing comprehensive measurement capabilities for diverse applications and environmental conditions. Sensor integration includes calibration, compensation, and validation ensuring accurate and reliable temperature data.

Sensor Technologies

- RTD Sensors: Platinum resistance temperature detectors with ±0.1°C accuracy

- Thermocouples: Wide temperature range sensors for high-temperature applications

- Thermistors: High-sensitivity sensors for precision temperature control

- Infrared Sensors: Non-contact temperature measurement for moving parts

- Fiber Optic Sensors: Distributed temperature sensing for extended monitoring

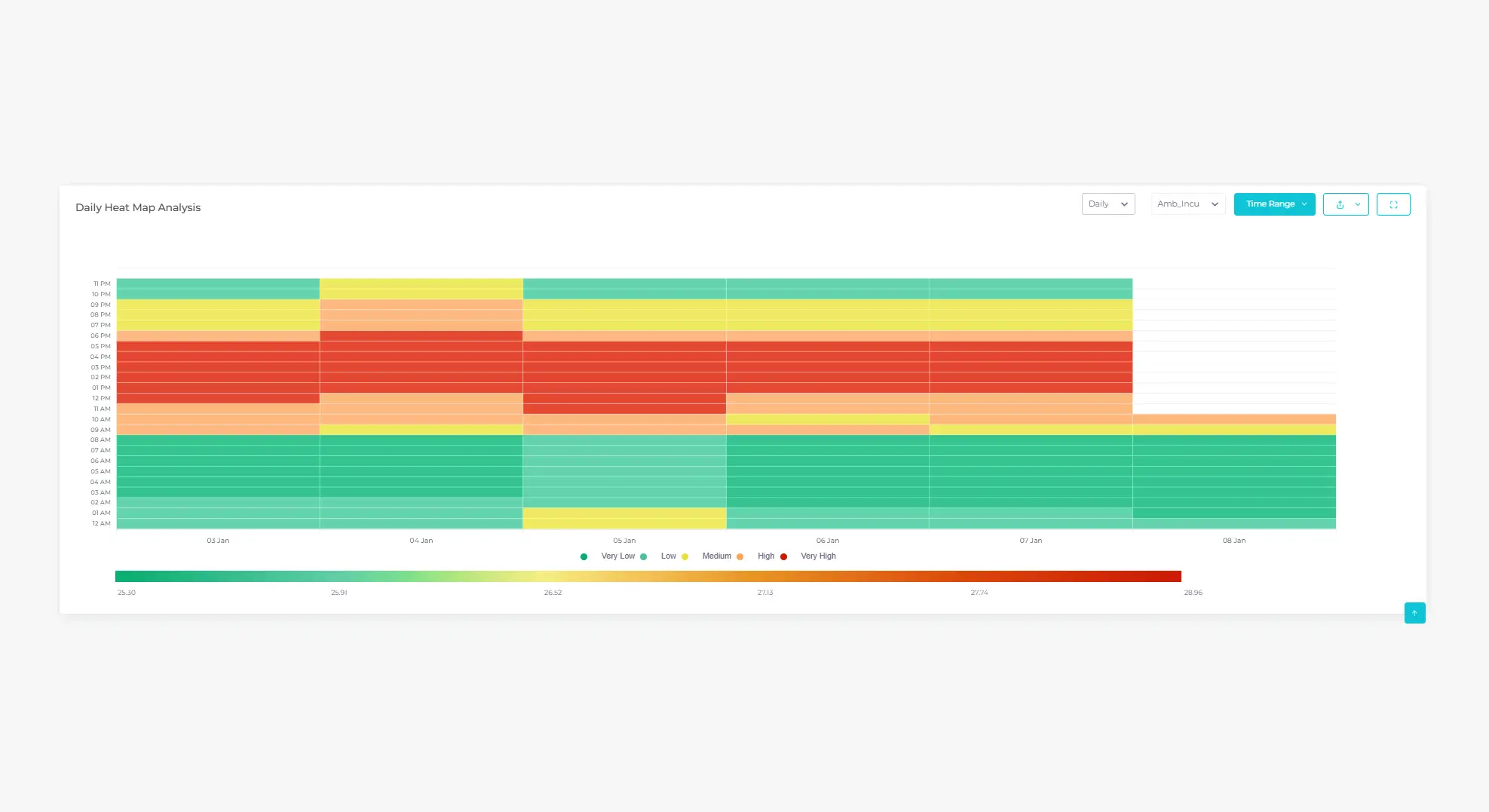

Real-Time Monitoring and Control

Continuous temperature monitoring with real-time data processing, trend analysis, and automated control response. Real-time capabilities enable immediate detection of temperature excursions and automatic corrective actions.

Real-Time Features

- Continuous Monitoring: 24/7 temperature monitoring with configurable sampling rates

- Instant Alerts: Real-time alarm generation for temperature excursions

- Automated Control: Automatic temperature control and correction systems

- Trend Analysis: Real-time trending and pattern recognition

- Data Logging: Comprehensive data logging for compliance and analysis

System Features and Capabilities

Core Platform Capabilities

- Multi-Point Monitoring: Simultaneous monitoring of hundreds of temperature points

- Wireless Connectivity: LoRa and Wi-Fi connectivity for remote monitoring

- Cloud Integration: Secure cloud connectivity for remote access and analytics

- Mobile Applications: Native mobile apps for remote monitoring and control

- Integration APIs: RESTful APIs for enterprise system integration

Advanced Control Algorithms

Intelligent control algorithms provide automated temperature regulation, predictive control, and optimization capabilities. Advanced algorithms adapt to changing conditions ensuring optimal thermal management and energy efficiency.

Control Features

- PID Control: Advanced PID algorithms for precise temperature regulation

- Predictive Control: Model predictive control for optimal thermal management

- Adaptive Algorithms: Self-tuning algorithms adapting to process changes

- Cascade Control: Multi-loop cascade control for complex thermal systems

- Feedforward Control: Disturbance compensation and feedforward control

Interested in advanced temperature monitoring capabilities? Contact our thermal engineers to explore DAVAS® temperature monitoring features and discuss implementation requirements for your thermal management application.

Professional Temperature Sensor Technologies and Specifications

Professional temperature monitoring utilizes multiple sensor technologies each optimized for specific applications, temperature ranges, and accuracy requirements. Sensor selection considers measurement range, accuracy, response time, environmental conditions, and installation requirements.

Resistance Temperature Detectors (RTDs)

RTD sensors provide the highest accuracy and stability for industrial temperature measurement using platinum resistance elements. RTDs offer excellent linearity, repeatability, and long-term stability making them ideal for precision applications.

RTD Specifications

- Temperature Range: -200°C to +850°C depending on construction

- Accuracy: ±0.1°C to ±0.3°C with proper calibration

- Response Time: 1-30 seconds depending on probe design

- Stability: ±0.05°C per year drift specification

- Standards: IEC 60751 and ASTM E1137 compliance

Thermocouples

Thermocouple sensors provide wide temperature range measurement using dissimilar metal junctions. Thermocouples offer fast response times, rugged construction, and wide temperature ranges for extreme applications.

Thermocouple Types and Specifications

- Type K (Chromel-Alumel): -270°C to +1372°C, ±1.1°C accuracy

- Type J (Iron-Constantan): -210°C to +1200°C, ±1.1°C accuracy

- Type T (Copper-Constantan): -270°C to +400°C, ±0.5°C accuracy

- Type R/S (Platinum): -50°C to +1768°C, ±1.0°C accuracy

- Type N (Nicrosil-Nisil): -270°C to +1300°C, improved stability

Thermistors

Thermistor sensors provide high sensitivity and precision for limited temperature range applications. Thermistors offer excellent resolution and fast response for precision temperature control applications.

Thermistor Characteristics

- Temperature Range: -80°C to +300°C for standard types

- Accuracy: ±0.05°C to ±0.2°C with calibration

- Sensitivity: High sensitivity enabling precise control

- Response Time: Fast response typically under 1 second

- Resolution: High resolution enabling small temperature changes detection

Infrared Temperature Sensors

Non-contact infrared sensors measure surface temperature without physical contact enabling measurement of moving parts, hazardous materials, and inaccessible locations. Infrared sensors provide fast response and long-term reliability.

Infrared Sensor Features

- Non-Contact Measurement: Safe measurement of hazardous or moving targets

- Fast Response: Millisecond response times for rapid temperature changes

- Wide Temperature Range: -40°C to +3000°C depending on sensor type

- Distance Capability: Measurement distances from millimeters to meters

- Spectral Ranges: Multiple spectral ranges for different applications

Need help selecting appropriate temperature sensors? Contact our sensor specialists to discuss temperature measurement requirements and receive recommendations for optimal sensor selection and specifications.

Advanced Temperature Control Systems and Automation

Temperature control systems provide automated thermal regulation using feedback control, predictive algorithms, and intelligent optimization. Control systems maintain optimal temperatures while minimizing energy consumption and maximizing process efficiency.

Control System Architecture

Comprehensive control system architecture integrating temperature sensors, control algorithms, actuators, and user interfaces. System architecture ensures reliable control performance and seamless integration with existing systems.

Control Components

- Temperature Sensors: Multi-point temperature measurement and feedback

- Control Algorithms: PID, predictive, and adaptive control algorithms

- Actuators: Heating elements, cooling systems, and valve control

- User Interfaces: Operator interfaces and remote monitoring capabilities

- Safety Systems: Interlocks, alarms, and emergency shutdown systems

Advanced Control Algorithms

Intelligent control algorithms optimize thermal performance through predictive control, adaptive tuning, and disturbance compensation. Advanced algorithms improve control accuracy while reducing energy consumption.

Algorithm Types

- PID Control: Proportional-integral-derivative control for precise regulation

- Model Predictive Control: Advanced predictive control for optimal performance

- Adaptive Control: Self-tuning algorithms adapting to process changes

- Fuzzy Logic Control: Fuzzy logic for complex non-linear systems

- Neural Network Control: AI-based control for learning systems

Heating and Cooling Systems

Integrated heating and cooling systems providing comprehensive thermal management capabilities. Systems include electric heating, steam heating, refrigeration, and air conditioning control.

Thermal System Types

- Electric Heating: Resistance heating, induction heating, and radiant systems

- Steam Systems: Steam heating control and condensate management

- Refrigeration: Mechanical refrigeration and chilled water systems

- Heat Pumps: Heat pump systems for heating and cooling applications

- Process Cooling: Industrial cooling systems and heat exchangers

Temperature Monitoring Implementation Services

Comprehensive implementation services including thermal system design, sensor installation, control system commissioning, and ongoing optimization. Professional implementation ensures optimal thermal management and maximum return on investment.

Thermal System Assessment

Detailed thermal assessment and analysis identifying temperature monitoring requirements, control objectives, and optimization opportunities. Assessment services provide baseline data and implementation recommendations.

Assessment Services

- Thermal Analysis: Comprehensive thermal analysis and heat transfer modeling

- Temperature Mapping: Detailed temperature mapping and profiling

- System Evaluation: Existing thermal system evaluation and optimization

- Requirement Analysis: Temperature monitoring and control requirement analysis

- ROI Analysis: Return on investment analysis and business case development

System Design and Engineering

Custom temperature monitoring system design including sensor selection, control strategy development, and integration specifications. Engineering services ensure optimal system performance and reliability.

Design Services

- Sensor Selection: Optimal sensor specification for application requirements

- Control Design: Control system architecture and algorithm development

- Installation Planning: Sensor placement and installation specification

- Integration Design: System integration and communication architecture

- Safety Design: Safety system design and compliance verification

Installation and Commissioning

Professional installation and commissioning services including sensor installation, control system configuration, testing, and performance verification. Installation ensures proper system operation and performance.

Installation Services

- Sensor Installation: Professional sensor mounting and connection

- System Configuration: DAVAS® platform setup and configuration

- Control Commissioning: Control system commissioning and tuning

- Testing and Validation: System testing and performance validation

- Training and Documentation: Operator training and system documentation

Ongoing Support and Optimization

Continuous support services including performance monitoring, system optimization, calibration, and maintenance. Ongoing support ensures continued accuracy and optimal performance.

Support Services

- Performance Monitoring: Continuous system performance monitoring and analysis

- System Optimization: Regular system optimization and tuning

- Calibration Services: Periodic sensor calibration and verification

- Technical Support: Expert technical support and troubleshooting

- System Updates: Software updates and feature enhancements

Need implementation support for your temperature monitoring project? Contact our implementation team to discuss your project requirements and develop a comprehensive deployment plan.

Industry-Specific Temperature Monitoring Applications

Temperature monitoring solutions serve diverse industries with unique thermal management requirements, process control needs, and regulatory compliance obligations. Industry-specific applications leverage temperature monitoring technology for quality control, safety compliance, and operational optimization.

Pharmaceutical and Life Sciences

Pharmaceutical temperature monitoring addressing cold chain management, manufacturing processes, and storage requirements. Applications ensure product efficacy, regulatory compliance, and quality assurance.

Pharmaceutical Applications

- Cold Chain Management: Vaccine and drug storage temperature monitoring

- Manufacturing Processes: Process temperature control and validation

- Clean Room Monitoring: Environmental temperature and humidity control

- Equipment Sterilization: Autoclave and sterilization temperature monitoring

- Stability Testing: Long-term stability testing environmental control

Food and Beverage Processing

Food industry temperature monitoring addressing food safety, process control, and regulatory compliance. Applications ensure product safety, quality, and compliance with HACCP requirements.

Food Processing Applications

- Food Safety: Critical control point temperature monitoring

- Cold Storage: Refrigeration and freezer temperature monitoring

- Cooking Processes: Cooking and pasteurization temperature control

- Transportation: Cold chain transportation monitoring

- Quality Control: Product temperature verification and validation

Chemical and Process Industries

Chemical process temperature monitoring addressing reaction control, safety requirements, and process optimization. Applications ensure safe operations, optimal yields, and regulatory compliance.

Chemical Process Applications

- Reaction Control: Chemical reaction temperature control and monitoring

- Distillation Processes: Distillation column temperature profiling

- Heat Exchanger Monitoring: Heat exchanger performance and efficiency

- Safety Systems: Temperature safety interlocks and protection

- Process Optimization: Temperature optimization for maximum efficiency

Manufacturing and Metalworking

Manufacturing temperature monitoring addressing equipment protection, process control, and quality assurance. Applications prevent overheating, optimize processes, and ensure product quality.

Manufacturing Applications

- Equipment Protection: Motor and bearing temperature monitoring

- Heat Treatment: Furnace and heat treatment temperature control

- Welding Processes: Welding temperature monitoring and control

- Machining Operations: Cutting tool and workpiece temperature monitoring

- Quality Control: Product temperature verification and testing

Data Centers and IT Infrastructure

Data center temperature monitoring addressing equipment protection, energy efficiency, and environmental control. Applications ensure reliable operations and optimal cooling efficiency.

Data Center Applications

- Server Monitoring: Server rack and equipment temperature monitoring

- Cooling Optimization: HVAC and cooling system optimization

- Hot Spot Detection: Data center hot spot identification and mitigation

- Energy Efficiency: Cooling energy optimization and PUE improvement

- Environmental Control: Data center environmental monitoring and control

Looking for industry-specific temperature monitoring solutions? Contact our industry experts to discuss temperature monitoring applications tailored to your specific industry requirements and regulatory standards.

Temperature Monitoring Standards and Regulatory Compliance

Temperature monitoring systems comply with industry standards and regulatory requirements ensuring accurate measurement, reliable operation, and regulatory compliance. Standards compliance provides confidence in measurement accuracy and supports regulatory reporting.

Measurement Standards

Professional temperature monitoring follows established measurement standards ensuring accuracy, traceability, and repeatability. Standards compliance supports regulatory requirements and quality assurance programs.

Industry Standards

- IEC 60751: Industrial platinum resistance thermometer standards

- ASTM E1137: RTD specification and temperature coefficient standards

- IEC 60584: Thermocouple standards and reference functions

- NIST ITS-90: International Temperature Scale calibration standards

- ISO 17025: Calibration laboratory competence and traceability

Regulatory Requirements

Temperature monitoring supports compliance with regulatory requirements including FDA validation, pharmaceutical regulations, and food safety standards. Regulatory compliance ensures legal adherence and quality assurance.

Regulatory Compliance

- FDA 21 CFR Part 11: Electronic records and signatures for pharmaceutical

- HACCP Requirements: Food safety critical control point monitoring

- GMP Compliance: Good manufacturing practice temperature requirements

- ISO 13485: Medical device quality management temperature control

- IATF 16949: Automotive quality management temperature monitoring

Calibration and Traceability

Comprehensive calibration and traceability programs ensure measurement accuracy and standards compliance. Calibration services maintain traceability to national standards and support regulatory requirements.

Calibration Services

- Initial Calibration: Factory and field calibration with certified standards

- Periodic Recalibration: Regular calibration verification and adjustment

- Traceability Documentation: Calibration certificates and traceability records

- Uncertainty Analysis: Measurement uncertainty evaluation and reporting

- Compliance Documentation: Regulatory compliance documentation and records

Temperature Monitoring ROI and Financial Benefits

Temperature monitoring systems deliver substantial return on investment through equipment protection, process optimization, energy savings, and quality improvements. ROI analysis includes cost savings, productivity improvements, and risk mitigation benefits.

Cost Reduction Benefits

Significant cost reductions achieved through equipment protection, energy optimization, and maintenance cost reduction. Cost analysis demonstrates rapid payback periods for temperature monitoring investments.

Cost Savings Areas

- Equipment Protection: Prevention of thermal damage and equipment failures

- Energy Savings: Thermal optimization reducing energy consumption

- Maintenance Reduction: Predictive maintenance reducing repair costs

- Quality Improvements: Reduced product defects and rework costs

- Insurance Benefits: Reduced insurance costs through risk mitigation

Productivity and Quality Benefits

Productivity improvements through process optimization, quality enhancement, and operational reliability. Quality benefits include reduced defects, improved consistency, and enhanced customer satisfaction.

Productivity Improvements

- Process Optimization: Optimized thermal processes improving productivity

- Quality Enhancement: Improved product quality and consistency

- Downtime Reduction: Reduced unplanned downtime and production losses

- Efficiency Gains: Improved operational efficiency and throughput

- Compliance Assurance: Regulatory compliance reducing compliance costs

Financial Analysis

Comprehensive financial analysis including implementation costs, operational savings, and payback calculations. Typical ROI for temperature monitoring ranges from 150-300% annually.

Financial Metrics

- Payback Period: Typical payback of 6-18 months for monitoring systems

- Annual ROI: 150-300% annual return on monitoring investment

- Lifecycle Benefits: Continued benefits throughout 5-10 year system life

- Risk Reduction: Reduced financial risk from thermal failures

- Compliance Value: Avoided regulatory penalties and compliance costs

Want to calculate ROI for your temperature monitoring investment? Contact our financial analysts to receive a customized ROI analysis and financial projection for your temperature monitoring system.

Take Action to Protect Your Electrical Systems

Don't let harmonic distortion damage expensive equipment or increase operating costs. Our comprehensive power quality audits identify problems before they cause failures, reduce energy consumption, and ensure IEEE 519 compliance.

Contact Three Phase Tech Services today to schedule your facility assessment and receive a detailed proposal tailored to your specific needs. Our experienced team will work with you to develop practical solutions that improve system reliability, reduce costs, and ensure long-term electrical system performance.

Ready to Start? Contact our power quality specialists for a consultation and customized assessment proposal.

Professional Power Quality Solutions

Electrical system reliability directly impacts productivity, equipment longevity, and operational costs. Our IEEE 519 compliant testing methodology and expert analysis help facilities reduce maintenance costs, improve energy efficiency, and eliminate costly equipment failures caused by power quality problems.

Take the first step toward electrical system reliability by scheduling a consultation with our power quality specialists. We'll review your facility requirements, discuss measurement options, and provide a customized proposal that addresses your specific concerns and budget requirements.

Professional Temperature Monitoring Commitment

3Phase Tech Services provides comprehensive temperature monitoring and control solutions that deliver reliable thermal management and measurable operational improvements. Our thermal specialists utilize proven DAVAS® technology and industry best practices to ensure successful implementations with maximum return on investment.

We understand that effective temperature monitoring requires precision measurement, reliable systems, and ongoing optimization to achieve thermal management objectives. Our temperature monitoring solutions are designed to provide comprehensive thermal oversight while delivering immediate benefits and long-term optimization.

Quality Assurance Program

Our quality assurance program includes sensor calibration, system testing, thermal analysis validation, and ongoing performance monitoring to ensure reliable operation and accurate temperature measurement throughout the system lifecycle.

Continuous Innovation

We continuously update our temperature monitoring capabilities, sensor technologies, and control algorithms to incorporate the latest thermal management advances and monitoring best practices for optimal client results.

Ready to implement comprehensive temperature monitoring for your facility? Contact our temperature monitoring specialists to discuss your thermal management requirements and develop a customized DAVAS® solution that delivers reliable temperature monitoring and measurable operational improvements.