Smart Solutions for Dynamic Production

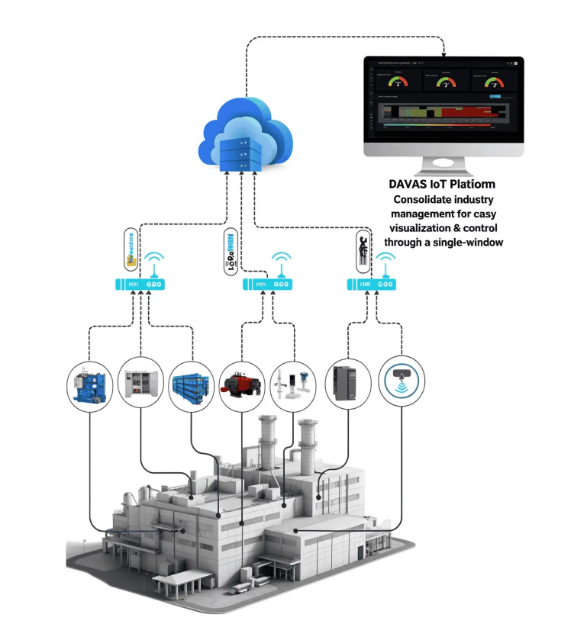

DAVAS® connects every machine across your facility, giving you full visibility and control over manufacturing operations from a unified dashboard. This ensures smoother workflows, greater efficiency, and real-time accessibility.

Professional smart factory management utilizes advanced Industrial Internet of Things (IIoT) technology, machine learning analytics, and automation systems to transform traditional manufacturing into intelligent, connected production environments. Smart factory solutions encompass real-time monitoring, predictive maintenance, quality control automation, and operational efficiency optimization.

Comprehensive manufacturing digitization includes equipment connectivity, data integration, process automation, and performance analytics. Smart factory management provides essential capabilities for modern manufacturing including production optimization, maintenance scheduling, quality assurance, and supply chain coordination to ensure competitive manufacturing operations.

3Phase Tech Services delivers professional smart factory management solutions including DAVAS® Industrial IoT platform implementation, system integration, automation design, and digital transformation services. Our manufacturing technology specialists utilize proven IoT platforms and industry best practices to provide comprehensive smart factory solutions that improve productivity and operational efficiency.

Send Enquiry

DAVAS® connects every machine across your facility, giving you full visibility and control over manufacturing operations from a unified dashboard. This ensures smoother workflows, greater efficiency, and real-time accessibility.

Single asset

Individual machine connectivity and monitoring establishing foundation for smart factory transformation. Single asset implementation provides real-time equipment data, performance metrics, and condition monitoring for critical manufacturing equipment.

Production line

Complete production line integration connecting multiple machines and processes for coordinated manufacturing operations. Production line implementation enables workflow optimization, quality tracking, and automated process control across interconnected equipment.

Factory

Facility-wide smart factory implementation connecting all production areas, support systems, and operational processes. Factory-level integration provides comprehensive manufacturing visibility, cross-departmental coordination, and enterprise-wide performance optimization.

Factory network

Multi-site smart factory network enabling coordinated operations across multiple manufacturing facilities. Factory network implementation provides global production visibility, resource optimization, and centralized manufacturing management capabilities.

The Future of Smart Factories

Predictive Analytics

Advanced algorithms detect anomalies and anticipate equipment failures, improving reliability and minimizing downtime.

Demand Forecasting

Edge Analytics supports accurate demand prediction and capacity planning, strengthening supply chain management.

Performance Monitoring

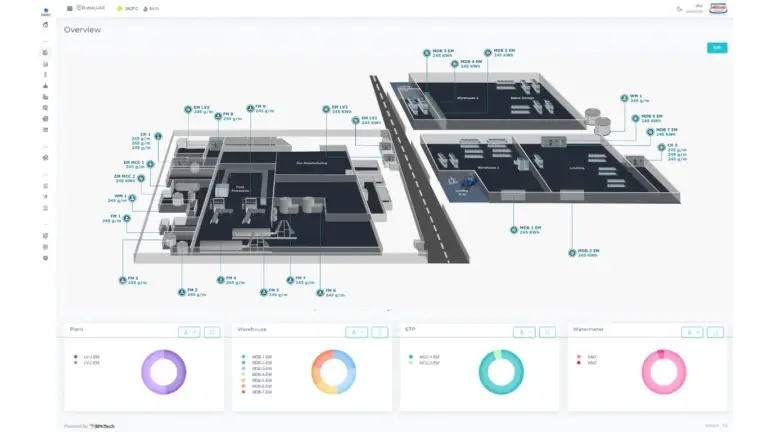

Real-time dashboards track production KPIs, highlight bottlenecks, and help optimize factory workflows.

Service Management

Automated ticketing and predictive maintenance enhance service delivery while reducing manual overhead.

Benefits

DAVAS® Industrial IoT Platform Capabilities

DAVAS® provides comprehensive Industrial Internet of Things platform for smart factory implementation with machine connectivity, data analytics, and automated control capabilities. Platform features include real-time monitoring, predictive analytics, workflow automation, and enterprise integration for complete manufacturing digitization.

Universal connectivity platform supporting diverse communication protocols and equipment types for comprehensive factory integration. DAVAS® connects legacy equipment and modern systems through standardized interfaces and protocol translation.

Frequently Asked Questions

What is smart factory management?

Smart factory management integrates IoT devices, automation systems, and data analytics to provide real-time visibility and control over manufacturing operations. It enables predictive maintenance, process optimization, and improved operational efficiency through connected manufacturing technologies.

Smart factory systems connect machines, processes, and people through digital platforms creating intelligent manufacturing environments with autonomous capabilities and data-driven decision making.

How does DAVAS improve manufacturing efficiency?

DAVAS connects machines across facilities providing unified dashboard control, real-time monitoring, predictive analytics, and automated workflow optimization. This reduces downtime, improves quality control, and increases overall equipment effectiveness (OEE).

Platform capabilities include machine connectivity, data analytics, process automation, and enterprise integration enabling comprehensive manufacturing digitization and operational optimization.

What industries can use smart factory solutions?

Smart factory management applies to automotive, aerospace, electronics, pharmaceuticals, food processing, and general manufacturing industries. Any facility with connected equipment and automation systems can benefit from IoT-enabled factory management.

Industry-specific applications address unique requirements including regulatory compliance, quality standards, and operational challenges while providing universal benefits of connectivity and automation.

Is DAVAS compatible with existing equipment?

Yes, DAVAS is designed for retrofit compatibility with existing manufacturing equipment through various communication protocols including Ethernet/IP, Modbus, OPC UA, and wireless connectivity options for seamless integration.

Legacy equipment integration utilizes protocol conversion and gateway devices enabling older systems to participate in smart factory operations without replacement requirements.

How long does smart factory implementation take?

Implementation typically requires 6-12 months for complete deployment depending on facility size and complexity. Phased implementation enables gradual deployment with immediate benefits from initial connectivity and monitoring.

What cybersecurity measures protect smart factories?

Smart factory cybersecurity includes network segmentation, access control, encryption, monitoring systems, and compliance with IEC 62443 standards. Multi-layered security protects operational technology from cyber threats.

Can smart factories operate autonomously?

Advanced smart factories achieve high levels of autonomy through AI and machine learning enabling self-optimization, predictive scheduling, and adaptive control. Human oversight remains essential for strategic decisions and exception handling.

What training is required for smart factory operations?

Operator training covers dashboard navigation, system monitoring, troubleshooting procedures, and data interpretation. Maintenance training includes system administration, configuration changes, and advanced troubleshooting techniques.

Industry 4.0 Technologies

Fourth industrial revolution technologies transforming manufacturing operations through cyber-physical systems, IoT connectivity, and data-driven decision making. Industry 4.0 implementation enables intelligent manufacturing with autonomous systems and human-machine collaboration.

Core Industry 4.0 Components

- Internet of Things (IoT): Connected devices and sensors throughout manufacturing operations

- Cyber-Physical Systems: Integration of physical processes with digital control systems

- Cloud Computing: Scalable data storage and processing for manufacturing analytics

- Big Data Analytics: Advanced data analysis for operational insights and optimization

- Artificial Intelligence: Machine learning and AI for predictive manufacturing operations

Digital Twin Technology

Virtual replicas of physical manufacturing systems enabling simulation, testing, and optimization without disrupting production operations. Digital twins provide real-time synchronization between physical and virtual environments for enhanced manufacturing control.

Digital Twin Applications

- Process Simulation: Virtual testing of manufacturing processes and optimization strategies

- Predictive Maintenance: Equipment health monitoring and failure prediction through digital models

- Product Development: Virtual prototyping and testing before physical production

- Quality Control: Real-time quality monitoring and defect prediction systems

- Training Systems: Virtual training environments for operators and maintenance personnel

Interested in future-ready manufacturing technology? Contact our Industry 4.0 experts to explore advanced smart factory technologies and develop a roadmap for your digital transformation journey.

Benefits

Smart factory management delivers comprehensive operational improvements through connected manufacturing systems, data-driven insights, and automated process optimization. Benefits include increased productivity, reduced costs, improved quality, and enhanced operational flexibility for competitive manufacturing advantage.

Operational Efficiency Improvements

Smart factory systems optimize manufacturing operations through real-time monitoring, automated workflow coordination, and performance analytics. Operational efficiency gains result from reduced waste, improved resource utilization, and streamlined production processes.

Efficiency Enhancement Areas

- Overall Equipment Effectiveness (OEE): Improved equipment utilization and performance optimization

- Production Throughput: Increased output through optimized workflows and reduced bottlenecks

- Resource Utilization: Better allocation of materials, energy, and human resources

- Cycle Time Reduction: Faster production cycles through process optimization

- Waste Minimization: Reduced material waste and energy consumption

Quality Control Enhancement

Automated quality monitoring and control systems ensure consistent product quality through real-time inspection, defect detection, and process adjustment. Smart factory quality systems reduce defects and improve customer satisfaction.

Quality System Features

- Real-Time Inspection: Continuous quality monitoring throughout production processes

- Defect Prevention: Predictive quality control preventing defects before occurrence

- Statistical Process Control: Data-driven quality management and process capability analysis

- Traceability Systems: Complete product traceability for quality assurance and compliance

- Automated Rejection: Automatic removal of defective products from production lines

Predictive Maintenance Capabilities

Advanced maintenance systems utilizing condition monitoring, predictive analytics, and automated scheduling to prevent equipment failures and optimize maintenance activities. Predictive maintenance reduces downtime and extends equipment life.

Maintenance System Benefits

- Failure Prevention: Early detection and prevention of equipment failures

- Reduced Downtime: Minimized unplanned maintenance and production interruptions

- Cost Optimization: Reduced maintenance costs through optimized scheduling

- Equipment Longevity: Extended equipment life through proper maintenance timing

- Spare Parts Management: Optimized inventory and parts availability

Want to quantify the benefits for your facility? Contact our ROI specialists to receive a customized smart factory benefits analysis and return on investment calculation for your manufacturing operations.

Smart Factory Implementation Services

Comprehensive smart factory implementation services including assessment, design, installation, commissioning, and ongoing support. Professional implementation ensures successful digital transformation with minimal disruption to production operations and maximum return on investment.

Assessment and Planning

Detailed facility assessment and implementation planning identifying automation opportunities, connectivity requirements, and integration challenges. Assessment services provide roadmap development and project prioritization for phased smart factory implementation.

Assessment Components

- Equipment Audit: Comprehensive evaluation of existing manufacturing equipment

- Connectivity Analysis: Assessment of communication capabilities and requirements

- Process Mapping: Documentation of current workflows and improvement opportunities

- ROI Analysis: Financial evaluation and benefit quantification

- Implementation Roadmap: Phased approach planning and timeline development

System Design and Engineering

Custom smart factory system design including network architecture, software configuration, and integration specifications. Engineering services ensure optimal system performance and seamless integration with existing operations.

Design Services

- Network Architecture: Communication network design and cybersecurity planning

- Software Configuration: DAVAS® platform customization and dashboard design

- Integration Planning: Enterprise system integration and data flow design

- Hardware Specification: Sensor selection and connectivity hardware requirements

- Documentation: Complete system documentation and operating procedures

Need implementation support for your smart factory project? Contact our implementation team to discuss your project requirements and develop a comprehensive implementation plan.

Industry-Specific Smart Factory Applications

Smart factory solutions adapt to diverse manufacturing industries with specialized requirements, regulations, and operational challenges. Industry-specific applications address unique manufacturing needs while providing comprehensive digitization and automation benefits.

Automotive Manufacturing

Smart factory solutions for automotive production including assembly line automation, quality control systems, and supply chain coordination. Automotive applications address high-volume production, quality requirements, and just-in-time manufacturing.

Automotive Applications

- Assembly Line Integration: Automated assembly process coordination and tracking

- Quality Assurance: Real-time inspection and defect detection systems

- Paint Shop Automation: Automated paint application and quality monitoring

- Logistics Coordination: Automated parts delivery and inventory management

- Traceability Systems: Complete vehicle and component traceability

Electronics Manufacturing

Smart factory applications for electronics production including surface mount technology (SMT) lines, testing systems, and clean room environments. Electronics manufacturing addresses precision requirements and rapid product changes.

Electronics Applications

- SMT Line Automation: Automated surface mount assembly and inspection

- Test Integration: Automated testing and data collection systems

- Clean Room Monitoring: Environmental control and contamination prevention

- Recipe Management: Automated product changeover and setup

- Yield Optimization: Real-time yield tracking and improvement

Looking for industry-specific smart factory solutions? Contact our industry experts to discuss smart factory applications tailored to your specific industry requirements and regulatory standards.

Smart Factory Technology Integration and Standards

Smart factory implementation requires integration of diverse technologies, communication protocols, and industry standards. Technology integration ensures interoperability, security, and scalability for comprehensive manufacturing digitization.

Communication Protocols

Industrial communication standards enabling device connectivity and data exchange in smart factory environments. Protocol support ensures compatibility with existing equipment and future technology adoption.

Supported Protocols

- Ethernet/IP: Industrial Ethernet protocol for real-time control applications

- Modbus TCP/RTU: Universal protocol for device communication and data access

- OPC UA: Platform-independent standard for industrial automation communication

- MQTT: Lightweight messaging protocol for IoT device communication

- Wireless Protocols: Wi-Fi, Bluetooth, and cellular connectivity options

Cybersecurity Standards

Industrial cybersecurity frameworks protecting smart factory systems from cyber threats and ensuring secure operations. Cybersecurity implementation follows IEC 62443 standards and best practices.

Security Features

- Network Segmentation: Isolated networks for operational technology protection

- Access Control: Role-based access control and user authentication

- Encryption: Data encryption for communication and storage security

- Monitoring Systems: Continuous security monitoring and threat detection

- Compliance: IEC 62443 and NIST cybersecurity framework compliance

Need help with technology integration planning? Contact our integration specialists to discuss technology requirements and develop a comprehensive integration strategy for your smart factory implementation.

Smart Factory Return on Investment and Performance Metrics

Smart factory investments deliver measurable returns through operational improvements, cost reductions, and productivity gains. ROI analysis includes equipment effectiveness, quality improvements, maintenance savings, and energy efficiency benefits.

Key Performance Indicators

Essential metrics for measuring smart factory performance and return on investment. KPIs provide quantitative assessment of operational improvements and financial benefits.

Primary KPIs

- Overall Equipment Effectiveness (OEE): Comprehensive equipment performance measurement

- First Pass Yield: Quality performance and defect reduction metrics

- Mean Time Between Failures (MTBF): Equipment reliability improvement

- Mean Time to Repair (MTTR): Maintenance efficiency and downtime reduction

- Energy Efficiency: Energy consumption per unit of production

Financial Benefits

Quantifiable financial returns from smart factory implementation including cost reductions, productivity improvements, and quality enhancements. Financial analysis provides business case justification and investment planning.

Cost Savings Areas

- Maintenance Costs: Reduced maintenance expenses through predictive strategies

- Quality Costs: Lower defect rates and quality-related expenses

- Energy Costs: Reduced energy consumption through optimization

- Labor Costs: Improved productivity and automated operations

- Inventory Costs: Reduced inventory through improved planning

Want to calculate ROI for your facility? Contact our ROI analysts to receive a customized financial analysis and return on investment projection for your smart factory implementation.

Professional Smart Factory Management Commitment

3Phase Tech Services provides comprehensive smart factory management solutions that deliver measurable results for manufacturing operations. Our industrial IoT specialists utilize proven DAVAS® platform technology and industry best practices to ensure successful digital transformation with maximum return on investment.

We understand that manufacturing digitization requires careful planning, expert implementation, and ongoing support to achieve operational excellence. Our smart factory solutions are designed to minimize disruption while maximizing benefits through phased implementation and comprehensive training programs.

Quality Assurance Program

Our quality assurance program includes system testing, performance verification, documentation review, and ongoing monitoring to ensure reliable operation and continuous improvement throughout the smart factory lifecycle.

Continuous Innovation

We continuously update our platform capabilities, integration methods, and industry knowledge to incorporate the latest manufacturing technologies and digital transformation best practices for optimal client results.

Ready to transform your manufacturing operations with smart factory technology? Contact our smart factory specialists to discuss your digital transformation goals and develop a comprehensive DAVAS® implementation strategy that delivers measurable operational improvements and competitive advantage.