Send Enquiry

Maximizing Energy Savings with Smart Energy Management

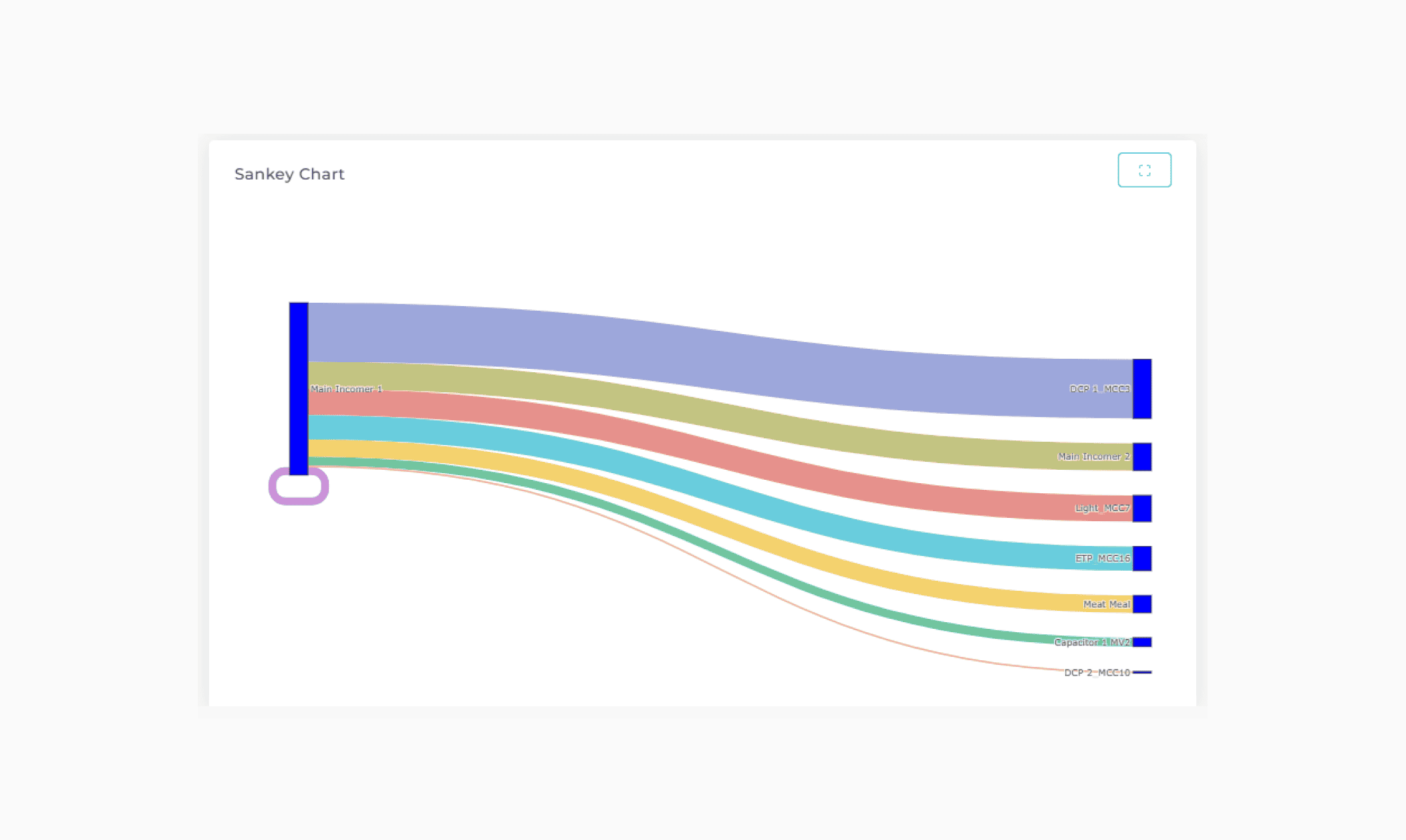

DAVAS combines IoT technology and advanced analytics to track, manage, and optimize energy usage while helping reduce electricity costs. With real-time data and intelligent controls, companies gain clear insights to improve operations and make energy-efficient decisions. By cutting waste and increasing efficiency, DAVAS supports sustainability goals and reduces carbon footprint—delivering both business and environmental benefits.

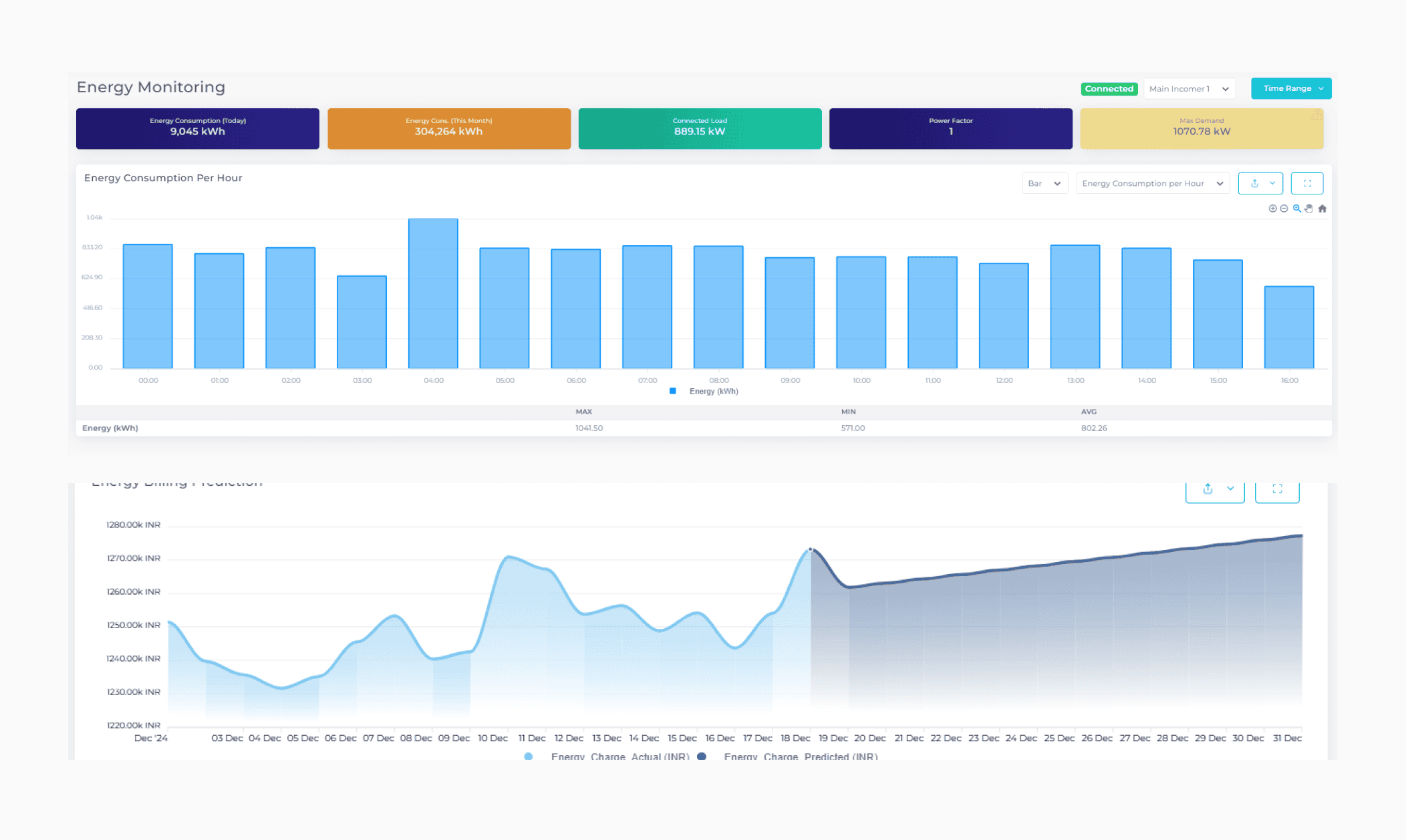

Turn Real-Time Energy Data into Action

DAVAS EnMS transforms energy data into actionable insights, helping companies make smarter decisions and achieve measurable cost savings.

Connectivity Options:

Wi-Fi and LoRa for dependable operation, even at remote sites

Flexible Deployment Models:

On-premise, hybrid, and cloud-based options to match your business setup

Are you aware that industries, enterprises & commercial spaces allocate upto 30% of their operational expenses to energy?

Energy costs represent a significant portion of operational expenses across industries, making energy management a critical business priority. Professional energy management systems address this challenge by providing comprehensive monitoring, analysis, and optimization capabilities that deliver substantial cost reductions and efficiency improvements.

Why Companies Choose DAVAS® EnMS

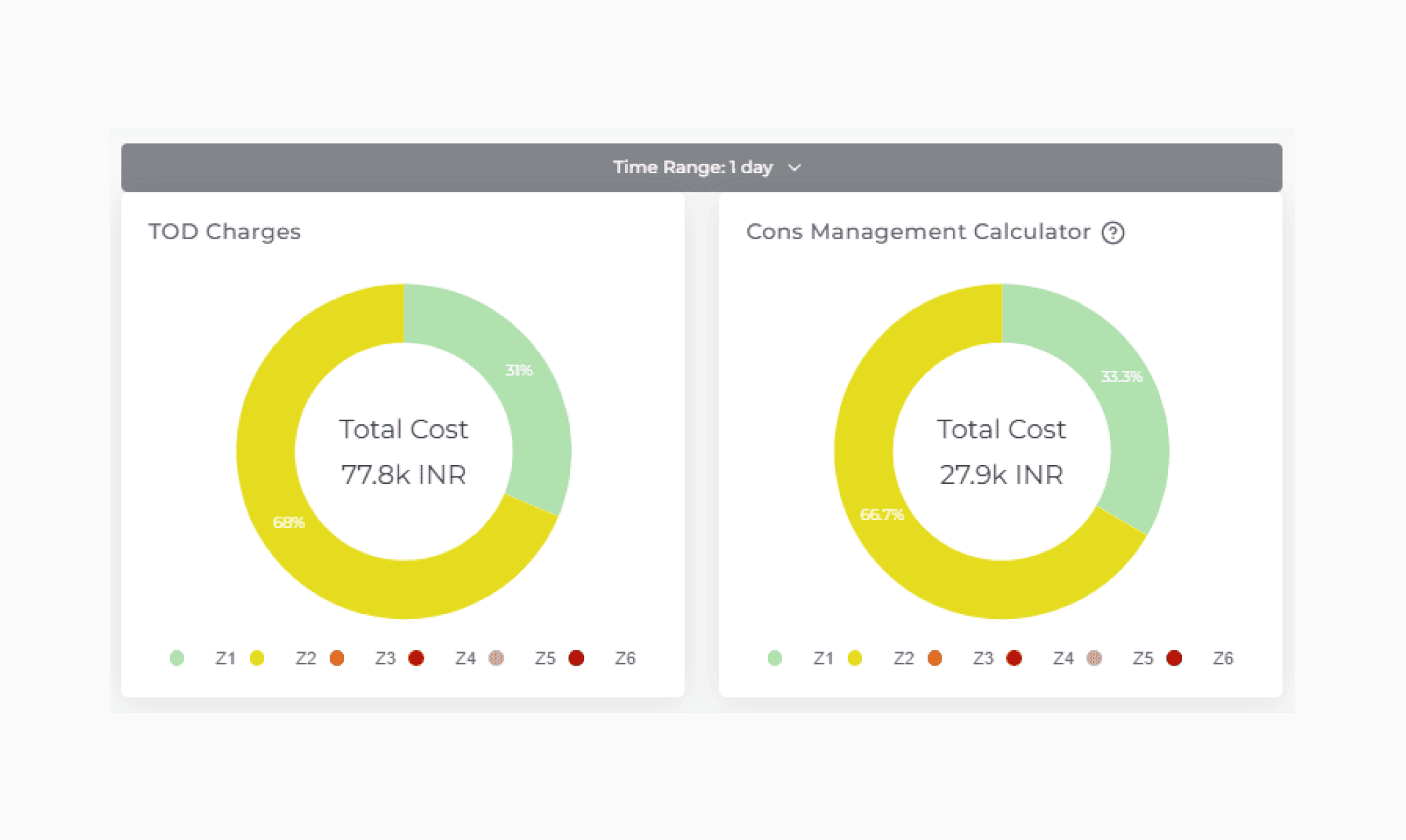

Strategic Energy Cost Management

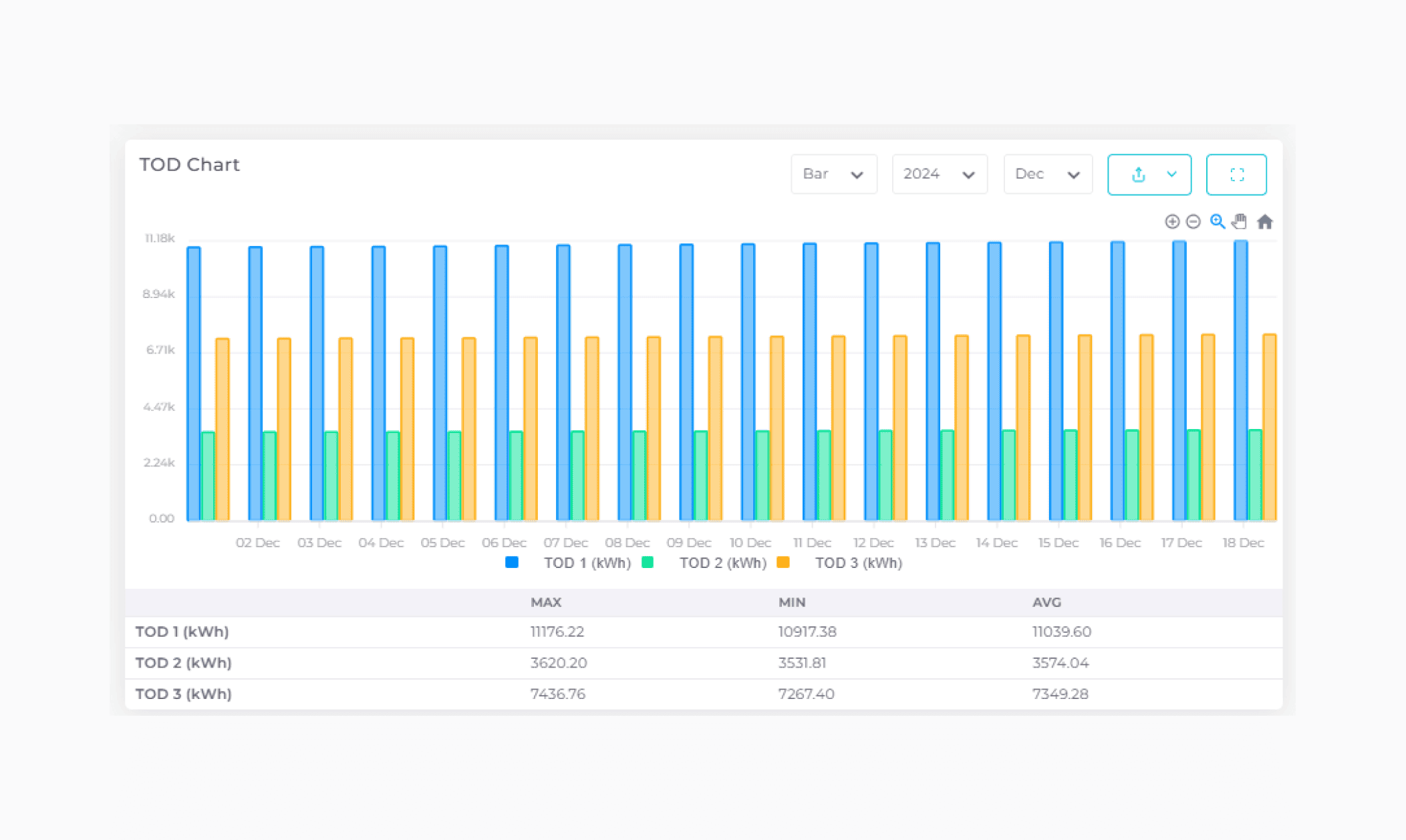

Simulate different load conditions to optimize forecasts and manage expenses effectively.

Time-of-Day Energy Insights

Analyze energy usage by time slots to identify savings and schedule operations more economically.

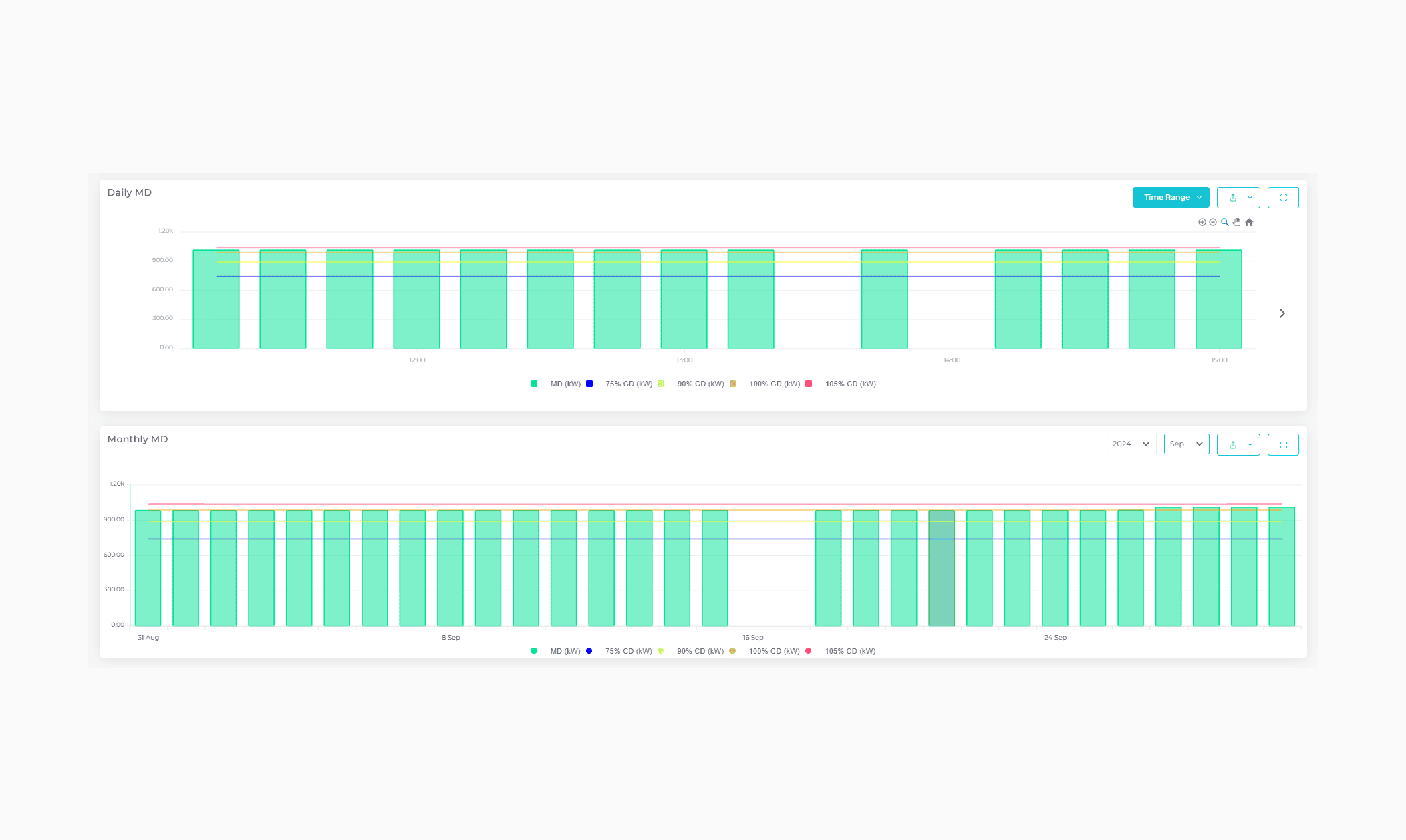

Balanced Energy Demand

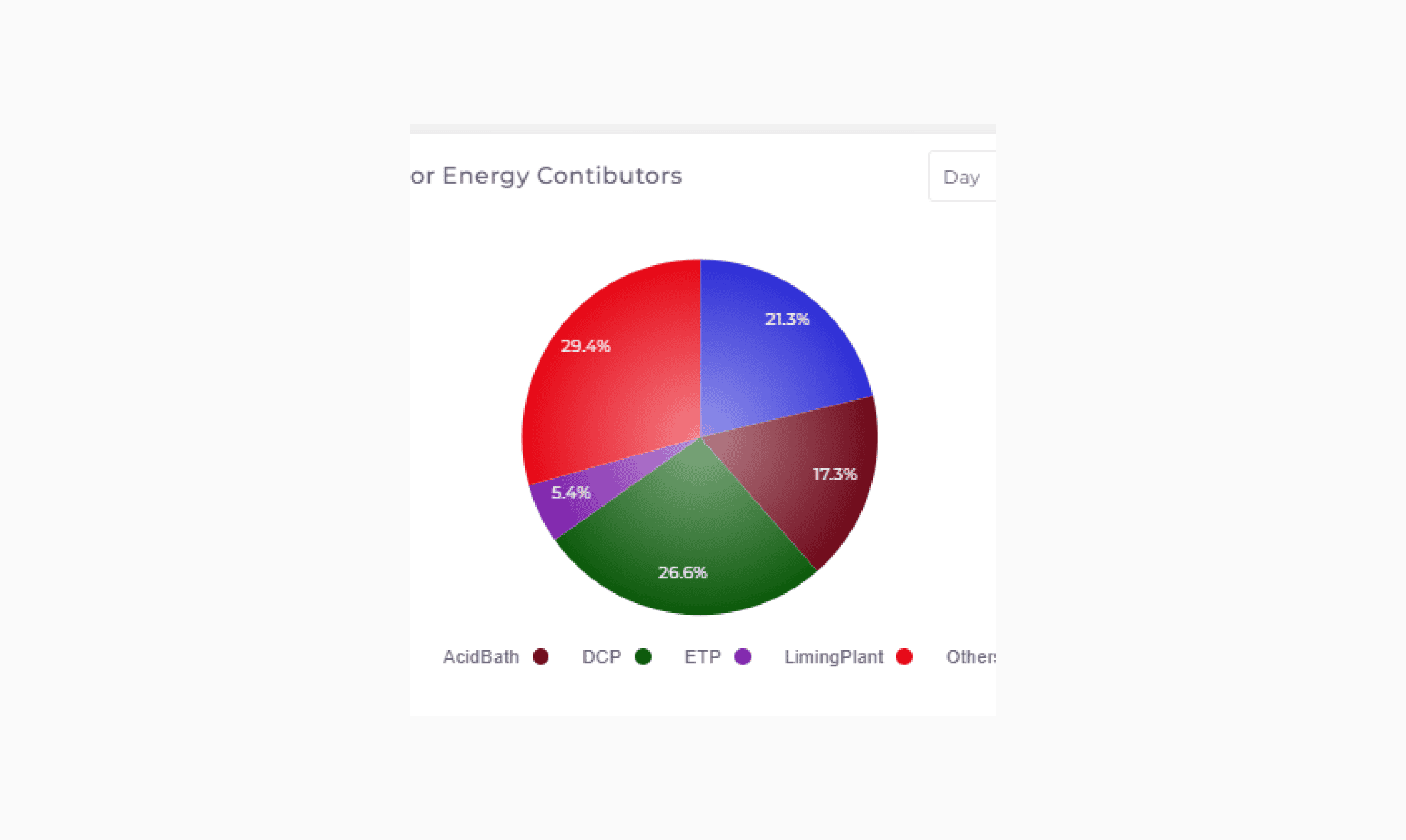

Key Cost Drivers at a Glance

Track and compare important energy parameters continuously to spot issues before they drive costs up.

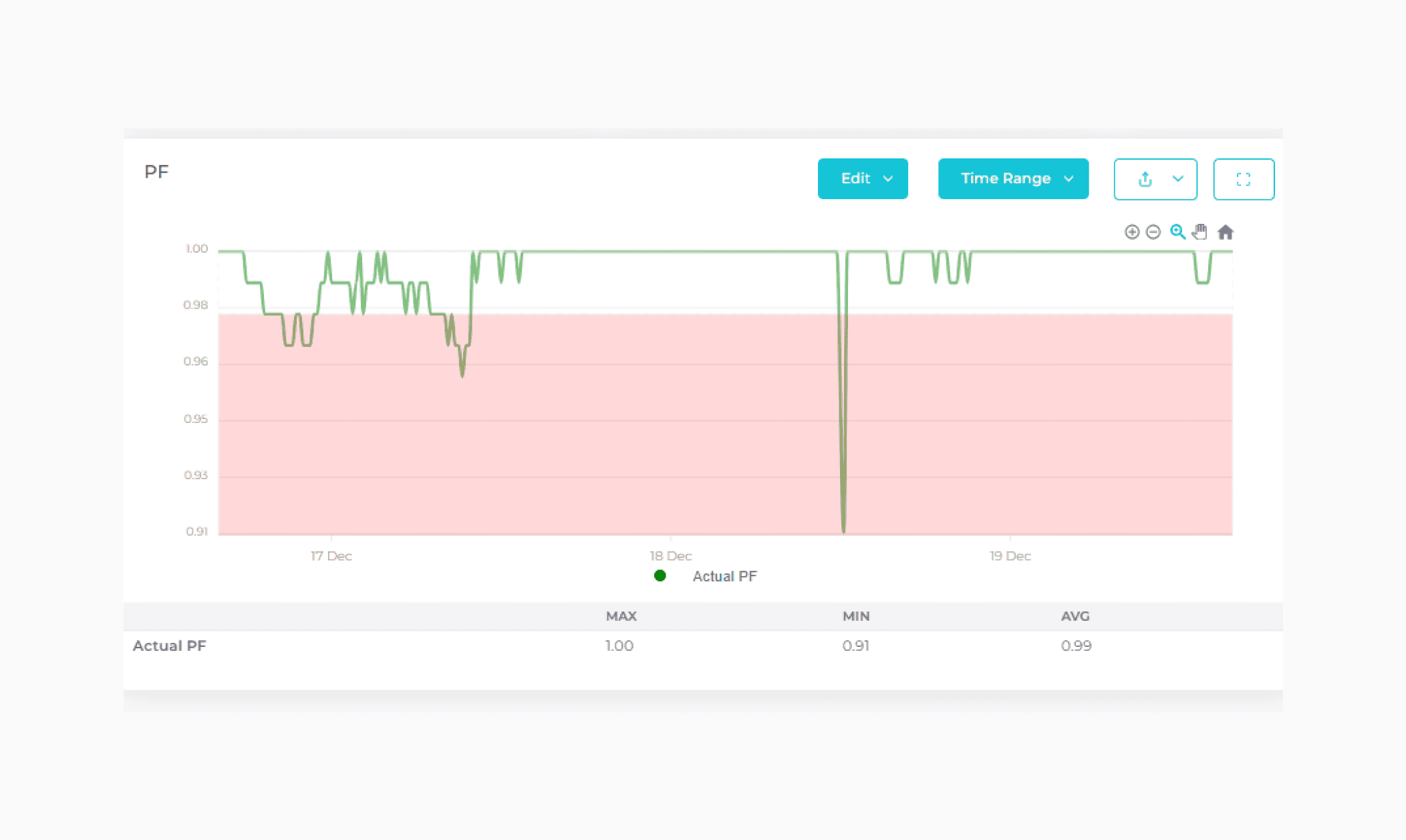

Power Factor Optimization

For kWh billing, DAVAS reduces wastage; for kVAh billing, it minimizes apparent power—cutting costs while improving efficiency. Power factor optimization is essential for reducing energy costs and improving electrical system efficiency. DAVAS® EnMS provides automated power factor correction, reactive power management, and power quality optimization to minimize utility penalties and reduce energy consumption.

Benefits You Gain

Simplify ISO 50001 Certification with DAVAS® EnMS

DAVAS® EnMS provides comprehensive ISO 50001 implementation support including energy policy development, objective setting, monitoring systems, and continuous improvement processes. ISO 50001 compliance ensures systematic energy management and continuous performance improvement.

ISO 50001 Framework Implementation

Complete ISO 50001 framework implementation including Plan-Do-Check-Act methodology, energy policy establishment, and management system development. Framework implementation ensures systematic approach to energy management and continuous improvement.

Frequently Asked Questions

What is an energy management system?

An energy management system (EnMS) is a comprehensive platform that monitors, analyzes, and optimizes energy consumption across facilities. It includes real-time monitoring, energy analytics, demand management, and automated control to reduce energy costs and improve efficiency.

Energy management systems integrate hardware and software components providing complete energy oversight, optimization capabilities, and continuous improvement processes for sustainable energy management.

How much can energy management systems save?

Energy management systems typically deliver 10-30% energy cost savings through optimization, demand management, and efficiency improvements. Actual savings depend on facility size, energy usage patterns, and system implementation scope.

Additional savings result from reduced maintenance costs, improved productivity, and extended equipment life through optimized operations and predictive maintenance capabilities.

What is ISO 50001 energy management?

ISO 50001 is an international standard for energy management systems that provides a framework for establishing energy policies, objectives, and continuous improvement processes. It helps organizations systematically reduce energy consumption and costs.

ISO 50001 implementation includes energy planning, baseline establishment, performance monitoring, and continuous improvement ensuring systematic approach to energy management and sustained results.

How does DAVAS EnMS improve energy efficiency?

DAVAS EnMS improves efficiency through real-time monitoring, automated optimization, demand response, power factor correction, and predictive analytics. It identifies energy waste, optimizes operations, and provides actionable insights for continuous improvement.

Platform capabilities include intelligent control algorithms, machine learning analytics, and automated optimization systems ensuring maximum efficiency and continuous performance improvement.

How long does energy management system implementation take?

Implementation typically requires 3-6 months for comprehensive systems depending on facility size and complexity. Implementation includes energy auditing, system design, installation, commissioning, and training phases.

What connectivity options are available for DAVAS EnMS?

DAVAS EnMS supports Wi-Fi, LoRa, Ethernet, cellular, and hybrid connectivity options ensuring reliable operation even at remote sites. Multiple connectivity options provide redundancy and operational flexibility.

Can energy management systems integrate with existing building systems?

Yes, DAVAS EnMS integrates with building management systems, SCADA systems, and enterprise software through standard protocols including Modbus, BACnet, and Ethernet/IP enabling centralized facility management.

What maintenance is required for energy management systems?

Maintenance includes software updates, calibration verification, communication system checks, and performance analysis. Professional maintenance ensures continued accuracy and system optimization.

DAVAS® Energy Management System Architecture

DAVAS® EnMS features comprehensive system architecture integrating energy monitoring devices, communication networks, data analytics, and control systems. The platform architecture ensures scalable deployment, secure communication, and seamless integration with existing facility systems and enterprise platforms.

System Components and Features

Core Platform Components

- Real-Time Monitoring: Continuous energy consumption tracking with high-resolution data

- Energy Analytics: Advanced analytics engine for consumption analysis and optimization

- Automated Control: Intelligent control systems for demand management and optimization

- Demand Management: Load shedding and peak demand reduction capabilities

- Power Quality Monitoring: Comprehensive power quality analysis and correction

- Reporting and Analytics: Automated reporting with customizable dashboards

- Mobile Access: Native mobile applications for remote monitoring and control

Integration Capabilities

DAVAS® EnMS integrates with existing building management systems, industrial control systems, and enterprise software through standard communication protocols and APIs. Integration capabilities enable centralized energy management and coordinated facility operations.

Integration Features

- BMS Integration: Seamless integration with building management systems

- SCADA Connectivity: Industrial SCADA system integration and data exchange

- ERP Integration: Enterprise resource planning system connectivity

- Protocol Support: Modbus, BACnet, Ethernet/IP, and wireless protocols

- Cloud Connectivity: Secure cloud integration for remote access and analytics

Interested in system architecture details? Contact our system architects to discuss DAVAS® EnMS architecture requirements and integration specifications for your facility.

Energy Cost Impact Analysis

Energy expenses significantly impact operational budgets across diverse industries, creating opportunities for substantial cost savings through effective energy management. Cost analysis reveals optimization potential and return on investment for energy management implementations.

Industry Energy Cost Breakdown

- Manufacturing: 25-35% of operational costs attributed to energy consumption

- Commercial Buildings: 20-30% of operating expenses for HVAC and lighting

- Data Centers: 40-50% of operational costs for cooling and IT equipment

- Healthcare Facilities: 15-25% of operating budgets for 24/7 operations

- Educational Institutions: 10-20% of operating expenses for campus facilities

Energy Management Opportunities

Significant energy savings opportunities exist through systematic energy management, equipment optimization, and operational improvements. Professional energy management systems identify and capture these opportunities through data-driven analysis and automated optimization.

Savings Opportunities

- Equipment Optimization: 10-20% savings through HVAC and equipment efficiency

- Demand Management: 15-25% reduction in peak demand charges

- Power Factor Improvement: 5-15% savings through power factor correction

- Operational Optimization: 10-30% savings through intelligent scheduling

Waste Elimination: 5-15% savings through energy waste identification

Power Factor Correction Benefits

Power factor correction delivers immediate cost savings through reduced utility penalties, improved system efficiency, and enhanced equipment performance. Correction systems automatically maintain optimal power factor levels reducing reactive power charges and demand penalties.

Optimization Benefits

- Utility Cost Reduction: Elimination of power factor penalties and charges

- System Efficiency: Improved electrical system efficiency and capacity

- Equipment Performance: Enhanced motor and equipment performance

- Voltage Regulation: Improved voltage stability and regulation

- Energy Savings: Reduced energy consumption through efficiency improvements

Automated Correction Systems

Intelligent power factor correction systems provide real-time monitoring and automatic capacitor switching for optimal power factor maintenance. Automated systems respond to changing load conditions ensuring consistent power factor optimization.

Correction Features

- Real-Time Monitoring: Continuous power factor and reactive power monitoring

- Automatic Switching: Intelligent capacitor bank switching and control

- Load Compensation: Dynamic compensation for varying load conditions

- Harmonic Filtering: Active harmonic filtering and power quality improvement

- Remote Control: Remote monitoring and control capabilities

Benefits You Gain

DAVAS® EnMS delivers comprehensive benefits through intelligent energy management, operational optimization, and continuous improvement. Benefits include significant cost savings, improved efficiency, enhanced sustainability, and regulatory compliance supporting business objectives and environmental goals.

Operational Cost Reduction

Substantial cost reductions achieved through energy optimization, demand management, and efficiency improvements. Cost reduction encompasses energy savings, demand charge reduction, power factor improvement, and operational optimization.

Cost Reduction Areas

- Energy Savings: 10-30% reduction in energy consumption and costs

- Demand Charges: 15-25% reduction in peak demand charges

- Power Factor: 5-15% savings through power factor optimization

- Maintenance Costs: Reduced maintenance through predictive management

- Operational Efficiency: Improved productivity through optimized operations

Enhanced System Performance

Improved system performance through optimized equipment operation, predictive maintenance, and intelligent control. Performance enhancements include equipment reliability, energy efficiency, and operational flexibility.

Performance Improvements

- Equipment Reliability: Enhanced equipment reliability and lifespan

- Energy Efficiency: Improved overall energy efficiency and performance

- System Optimization: Optimized system operation and control

- Predictive Maintenance: Predictive maintenance reducing downtime

- Operational Flexibility: Enhanced operational flexibility and responsiveness

Regulatory Compliance and Sustainability

Comprehensive compliance support for energy regulations, sustainability initiatives, and environmental reporting. Compliance capabilities include ISO 50001 implementation, carbon footprint reduction, and regulatory reporting.

Compliance Benefits

- ISO 50001 Compliance: Complete ISO 50001 energy management system implementation

- Carbon Reporting: Automated carbon footprint calculation and reporting

- Regulatory Compliance: Energy efficiency regulation compliance and reporting

- Sustainability Goals: Support for corporate sustainability initiatives

- Green Certifications: LEED, BREEAM, and other green building certifications

Energy Management System Implementation Services

Comprehensive energy management implementation services including energy auditing, system design, installation, commissioning, and ongoing optimization. Professional implementation ensures successful deployment, optimal performance, and maximum return on investment.

Energy Audit and Assessment

Detailed energy auditing and assessment services identifying energy consumption patterns, efficiency opportunities, and optimization potential. Energy audits provide baseline data and improvement recommendations for energy management system implementation.

Audit Services

- Comprehensive Energy Audit: Detailed facility energy consumption analysis

- Equipment Assessment: HVAC, lighting, and equipment efficiency evaluation

- Baseline Development: Energy baseline establishment and benchmarking

- Opportunity Identification: Energy savings opportunity identification and prioritization

- ROI Analysis: Return on investment analysis for improvement recommendations

System Design and Engineering

Custom energy management system design including monitoring architecture, control strategies, and integration specifications. Engineering services ensure optimal system performance and seamless integration with existing facility systems.

Design Services

- Monitoring Design: Energy monitoring system architecture and sensor placement

- Control Strategy: Automated control strategy development and optimization

- Integration Planning: BMS and enterprise system integration design

- Communication Networks: Communication network design and cybersecurity planning

- User Interface: Dashboard and user interface design and customization

Installation and Commissioning

Professional installation and commissioning services including equipment installation, system configuration, testing, and performance verification. Installation ensures proper system operation and achievement of design objectives.

Installation Services

- Equipment Installation: Monitoring device and control system installation

- System Configuration: DAVAS® EnMS platform setup and configuration

- Testing and Verification: System testing and performance verification

- User Training: Comprehensive operator and administrator training

- Documentation: Complete system documentation and user manuals

Ongoing Optimization and Support

Continuous optimization and support services including performance monitoring, system tuning, and improvement identification. Ongoing services ensure continued performance and adaptation to changing requirements.

Support Services

- Performance Monitoring: Continuous system performance monitoring and analysis

- System Optimization: Regular system tuning and optimization

- Energy Analysis: Ongoing energy analysis and improvement identification

- Technical Support: Expert technical support and troubleshooting

- Software Updates: Regular software updates and feature enhancements

Need implementation support for your energy management project? Contact our implementation team to discuss your project requirements and develop a comprehensive deployment strategy.

Industry-Specific Energy Management Applications

Energy management systems serve diverse industries with unique energy requirements, operational challenges, and regulatory compliance needs. Industry-specific applications leverage energy management technology for cost reduction, efficiency optimization, and sustainability initiatives.

Manufacturing and Industrial

Industrial energy management addressing production processes, equipment optimization, and utility management. Manufacturing applications focus on energy cost reduction, process efficiency, and demand management for competitive operations.

Manufacturing Applications

- Process Optimization: Energy-intensive process monitoring and optimization

- Equipment Management: Industrial equipment energy monitoring and control

- Utility Management: Compressed air, steam, and cooling system optimization

- Production Scheduling: Energy-aware production scheduling and optimization

- Demand Management: Peak demand management and load shedding strategies

Commercial Real Estate

Commercial building energy management including HVAC optimization, lighting control, and tenant billing. Commercial applications focus on operating cost reduction, tenant satisfaction, and building performance optimization.

Commercial Applications

- HVAC Optimization: Building HVAC system efficiency and comfort optimization

- Lighting Control: Intelligent lighting control and energy management

- Tenant Sub-Metering: Individual tenant energy monitoring and billing

- Building Performance: Overall building energy performance optimization

- Peak Demand Management: Building peak demand reduction and management

Healthcare Facilities

Healthcare energy management addressing critical systems, patient comfort, and regulatory compliance. Healthcare applications ensure patient safety while optimizing energy consumption and operational costs.

Healthcare Applications

- Critical System Monitoring: Critical HVAC and power system monitoring

- Environmental Control: Patient area environmental control and optimization

- Equipment Management: Medical equipment energy monitoring and management

- Emergency Systems: Backup power and emergency system management

- Compliance Support: Regulatory compliance monitoring and reporting

Educational Institutions

Campus energy management including multiple buildings, dormitories, and research facilities. Educational applications support both operational efficiency and sustainability education initiatives.

Educational Applications

- Campus-Wide Monitoring: Multi-building energy monitoring and control

- Dormitory Management: Student housing energy management and billing

- Research Facility Control: Laboratory and research facility energy optimization

- Sustainability Education: Student sustainability engagement and education

- Budget Management: Energy budget management and cost allocation

Looking for industry-specific energy management solutions? Contact our industry experts to discuss energy management applications tailored to your specific industry requirements.

Energy Management System ROI and Financial Benefits

Energy management systems deliver substantial return on investment through energy cost reduction, operational efficiency improvements, and sustainability benefits. ROI analysis includes energy savings quantification, maintenance cost reduction, and productivity improvements from optimized energy management.

Financial Benefits Analysis

Comprehensive financial benefits including direct energy savings, demand charge reduction, power factor improvement, and operational cost reductions. Financial analysis provides business case justification and investment planning support.

Primary Financial Benefits

- Energy Cost Savings: 10-30% reduction in overall energy costs

- Demand Charge Reduction: 15-25% reduction in peak demand charges

- Power Factor Savings: 5-15% savings through power factor optimization

- Maintenance Savings: Reduced maintenance costs through predictive management

- Productivity Improvements: Enhanced productivity through optimized operations

Implementation ROI

Typical return on investment for energy management systems ranges from 12-24 months depending on facility size, energy consumption patterns, and implementation scope. ROI calculation includes all system costs and quantified benefits.

ROI Factors

- Payback Period: Typical payback of 1-2 years for comprehensive systems

- Annual Savings: 20-40% annual return on energy management investment

- Lifecycle Benefits: Continued benefits throughout 10-15 year system lifecycle

- Incentive Programs: Utility and government incentives reducing initial costs

- Avoided Costs: Avoided energy infrastructure and upgrade costs

Value-Added Benefits

Additional value-added benefits including improved sustainability, regulatory compliance, competitive advantage, and enhanced building value. Value-added benefits extend beyond direct cost savings to strategic business benefits.

Strategic Benefits

- Sustainability Leadership: Corporate sustainability and environmental leadership

- Regulatory Compliance: Energy efficiency regulation compliance and reporting

- Competitive Advantage: Lower operating costs providing competitive advantage

- Asset Value: Increased building and facility asset value

- Risk Mitigation: Energy cost volatility risk mitigation and management

Want to calculate ROI for your energy management investment? Contact our financial analysts to receive a customized ROI analysis and financial projection for your energy management system.

Professional Energy Management System Commitment

3Phase Tech Services provides comprehensive energy management solutions that deliver measurable results and sustainable cost savings. Our energy management specialists utilize proven DAVAS® EnMS technology and industry best practices to ensure successful implementations with maximum return on investment and continuous performance improvement.

We understand that effective energy management requires systematic approach, professional implementation, and ongoing optimization to achieve sustainability objectives. Our energy management solutions are designed to provide comprehensive energy oversight while delivering immediate cost savings and long-term efficiency improvements.

Quality Assurance Program

Our quality assurance program includes system testing, performance verification, energy audit validation, and ongoing monitoring to ensure reliable operation and continued optimization throughout the energy management system lifecycle.

Continuous Innovation

We continuously update our energy management capabilities, analytics algorithms, and optimization techniques to incorporate the latest energy technologies and management best practices for optimal client results and future-ready solutions.

Ready to implement comprehensive energy management for your facility? Contact our energy management specialists to discuss your energy optimization objectives and develop a customized DAVAS® EnMS solution that delivers measurable savings and sustainable performance improvements.