Effortless Energy Optimization with DAVAS® BTU Monitoring

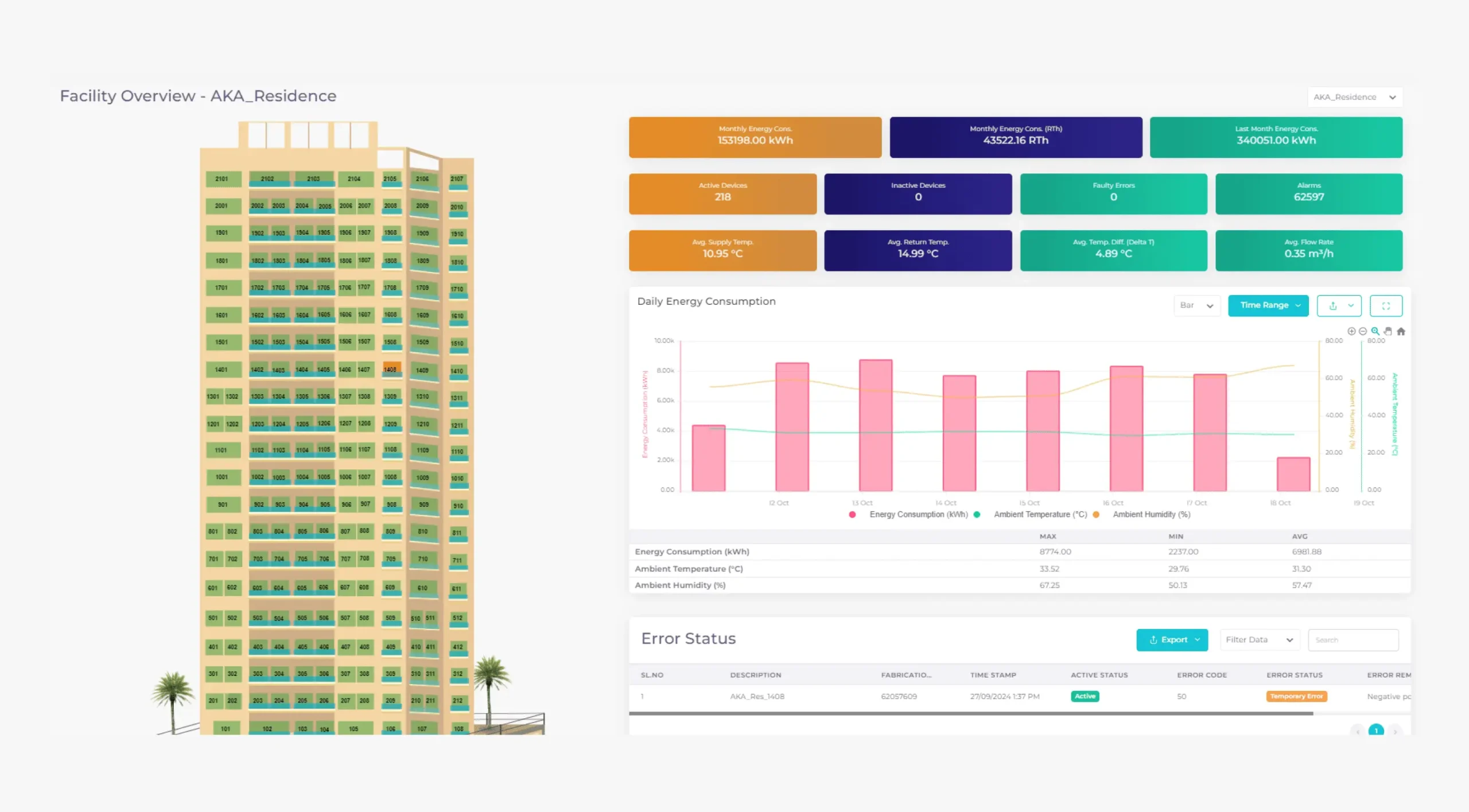

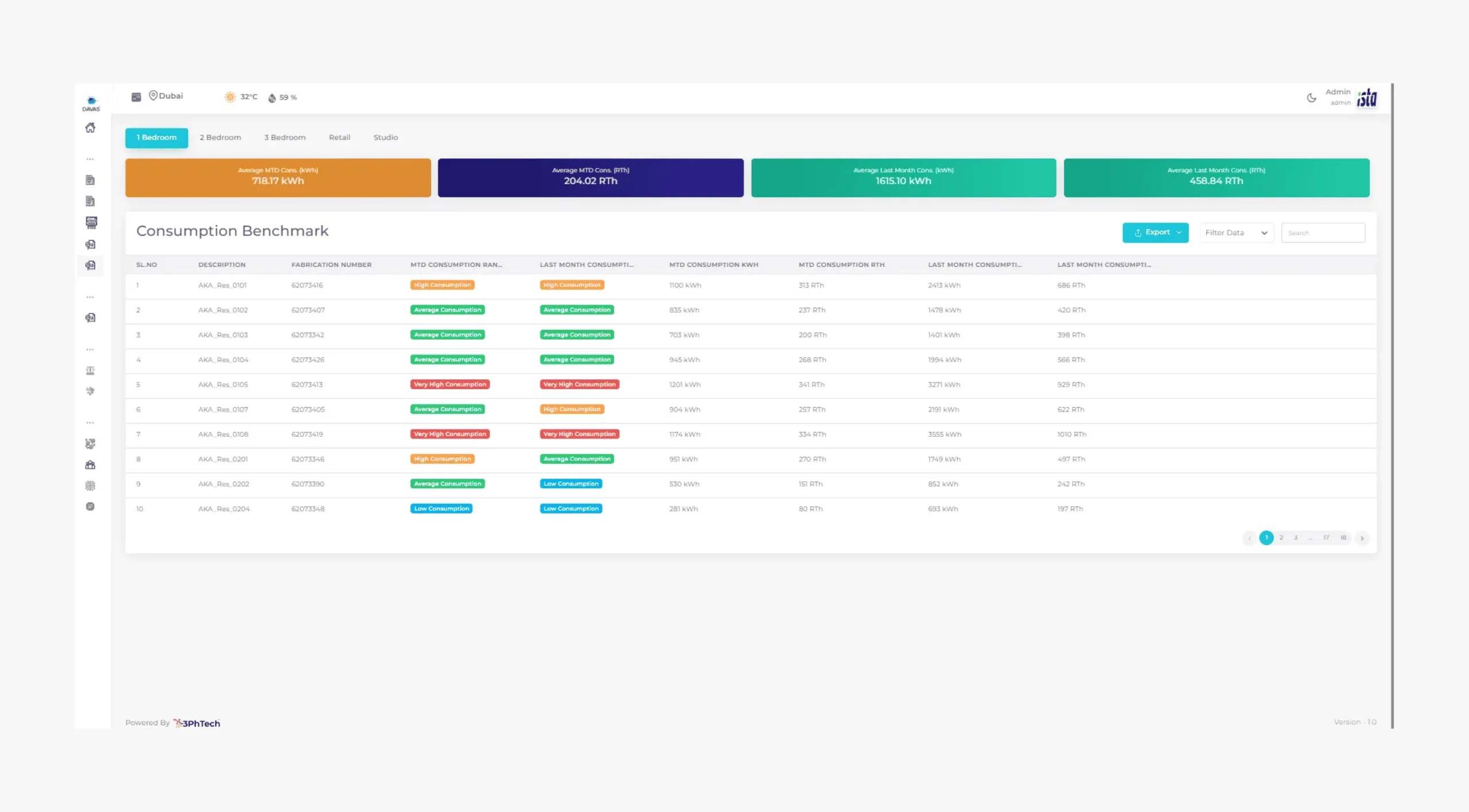

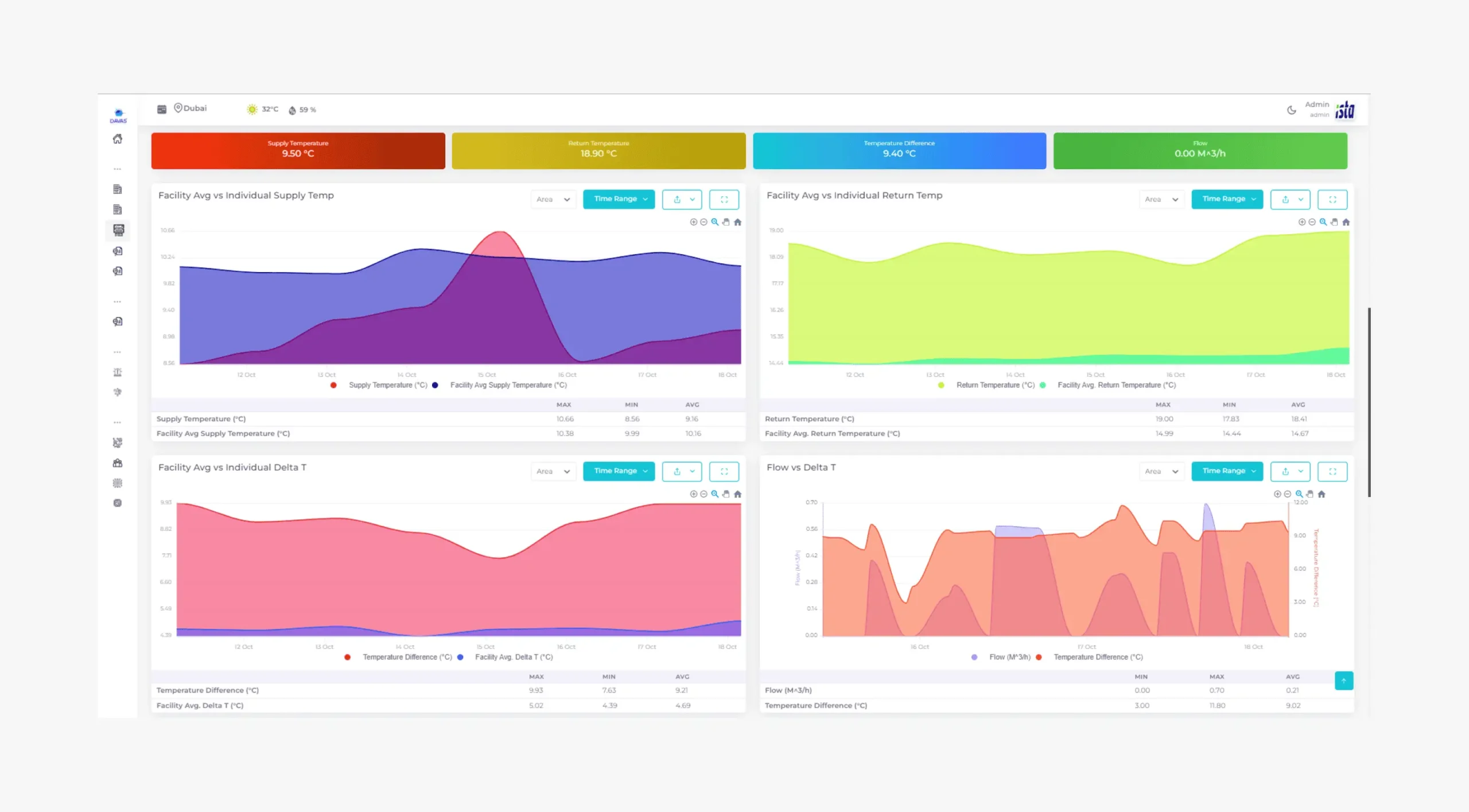

DAVAS® BTU Monitoring Solution provides comprehensive thermal energy measurement and analysis for HVAC systems, industrial processes, and building energy management. Advanced BTU monitoring enables precise energy consumption tracking, efficiency optimization, and cost reduction through accurate thermal energy measurement and data analytics.

Send Enquiry

Key Features

Benefits

Smarter Cost Management

Detailed energy insights highlight opportunities for cost savings and improved budget control. BTU monitoring provides granular energy consumption data enabling identification of inefficient equipment, peak demand periods, and optimization opportunities. Cost management benefits include accurate energy accounting, budget forecasting, and ROI analysis for energy efficiency investments.

Clear Operational Visibility

Comprehensive energy reports provide actionable data for better decision-making. Operational visibility through real-time dashboards, trending analysis, and comprehensive reporting enables informed decision-making for energy management and system optimization. Clear visibility identifies operational patterns and improvement opportunities.

Predictive Maintenance

Detects early signs of system issues, helping reduce downtime and extending asset life. Predictive maintenance capabilities identify equipment degradation through energy consumption patterns, efficiency trends, and performance anomalies. Early detection prevents catastrophic failures and extends equipment life through timely maintenance interventions.

Sustainable Growth

Monitoring solutions expand with your business, ensuring efficiency keeps pace with demand. Scalable BTU monitoring architecture accommodates facility expansion, additional systems, and growing energy management requirements. Sustainable growth ensures continued efficiency optimization as operations expand and energy demands increase.

Frequently Asked Questions

What is BTU monitoring?

BTU monitoring measures and tracks thermal energy consumption in heating, cooling, and industrial processes using temperature and flow sensors. It calculates British Thermal Units to quantify energy usage, efficiency, and costs for HVAC systems and thermal equipment.

BTU monitoring systems provide real-time energy consumption data, historical trending, and efficiency analysis enabling optimization of thermal systems and energy cost management.

How accurate is BTU measurement?

Professional BTU monitoring systems achieve accuracy levels of ±1-2% when properly calibrated and installed. Accuracy depends on sensor quality, installation methods, and environmental conditions affecting temperature and flow measurements.

Accuracy is maintained through proper sensor selection, professional installation, regular calibration, and appropriate system design for specific applications.

What HVAC systems benefit from BTU monitoring?

BTU monitoring benefits chilled water systems, hot water heating, steam systems, cooling towers, air handling units, and geothermal systems. Any HVAC system with measurable flow and temperature differential can utilize BTU monitoring for efficiency optimization.

Systems with significant thermal loads and variable operation patterns achieve the greatest benefits from BTU monitoring and optimization.

How does BTU monitoring reduce energy costs?

BTU monitoring reduces energy costs by identifying inefficient equipment, optimizing system operation, enabling demand-based control, and providing data for energy management decisions. Typical energy savings range from 10-30% through improved system efficiency.

Cost reduction results from operational optimization, predictive maintenance, peak demand management, and targeted efficiency improvements based on measured data.

What sensors are used for BTU monitoring?

BTU monitoring uses precision temperature sensors (RTDs, thermistors) and flow sensors (ultrasonic, magnetic, turbine) to measure thermal energy transfer. Sensor selection depends on application requirements, fluid types, and accuracy specifications.

How long does BTU monitoring system installation take?

Installation typically requires 1-3 days per system depending on complexity and sensor locations. Installation includes sensor mounting, wiring, system configuration, calibration, and commissioning.

Can BTU monitoring integrate with existing building systems?

Yes, BTU monitoring systems integrate with building management systems, energy management platforms, and enterprise software through standard protocols including BACnet, Modbus, and Ethernet/IP.

What maintenance is required for BTU monitoring systems?

Maintenance includes periodic calibration verification, sensor cleaning, connection inspection, and system performance checks. Professional maintenance ensures continued accuracy and system reliability.

Advanced BTU Measurement Technology and Calculation Methods

BTU (British Thermal Unit) measurement technology utilizes precision sensors and advanced calculation algorithms to determine thermal energy consumption in heating, cooling, and industrial processes. Professional BTU monitoring systems provide accurate energy measurement essential for efficiency optimization and cost management.

BTU Calculation Fundamentals

BTU calculation determines thermal energy transfer using flow rate, temperature differential, and fluid properties. Mathematical algorithms account for fluid density, specific heat, and temperature compensation ensuring accurate energy measurement across varying operating conditions.

Calculation Components

- Flow Rate Measurement: Volumetric or mass flow measurement using calibrated sensors

- Temperature Differential: Supply and return temperature measurement with precision sensors

- Fluid Properties: Density and specific heat calculations based on fluid type and temperature

- Energy Calculation: BTU = Flow Rate × Temperature Differential × Specific Heat × Density

- Totalization: Accumulated energy consumption over specified time periods

Sensor Technologies

Professional BTU monitoring utilizes high-accuracy sensors for temperature and flow measurement ensuring reliable energy calculation. Sensor selection depends on application requirements, fluid types, and accuracy specifications.

Temperature Sensors

- RTD Sensors: Platinum resistance temperature detectors with ±0.1°C accuracy

- Thermistor Sensors: High-sensitivity temperature measurement for precision applications

- Thermocouple Sensors: Wide temperature range sensors for industrial applications

- Matched Pairs: Calibrated sensor pairs minimizing measurement errors

- Insertion Sensors: Hot-tap installation capability for retrofit applications

Flow Measurement Technologies

- Ultrasonic Flow Meters: Non-invasive flow measurement with clamp-on sensors

- Magnetic Flow Meters: Inline flow measurement for conductive fluids

- Turbine Flow Meters: Mechanical flow measurement with high accuracy

- Vortex Flow Meters: Steam and gas flow measurement capability

- Differential Pressure: Orifice plate and Venturi tube flow measurement

Data Processing and Compensation

Advanced data processing algorithms compensate for environmental factors, sensor drift, and system variations ensuring consistent BTU measurement accuracy. Processing includes calibration, linearization, and error correction for reliable energy data.

Processing Features

- Temperature Compensation: Automatic compensation for ambient temperature effects

- Pressure Compensation: Pressure correction for accurate flow measurement

- Drift Compensation: Automatic sensor drift correction and calibration

- Linearization: Sensor output linearization for improved accuracy

- Validation: Data validation and quality assurance algorithms

Need detailed BTU measurement specifications? Contact our measurement engineers to discuss technical requirements and sensor specifications for your BTU monitoring application.

Industry-Specific BTU Monitoring Applications

BTU monitoring solutions serve diverse industries with unique energy management requirements, regulatory compliance needs, and operational challenges. Industry-specific applications leverage BTU measurement technology for efficiency optimization, cost reduction, and sustainability initiatives.

Commercial Buildings and Offices

BTU monitoring for commercial HVAC systems including chilled water distribution, hot water heating, and energy sub-metering for tenant billing. Commercial applications focus on energy cost reduction and tenant accountability.

Commercial Applications

- Tenant Sub-Metering: Individual tenant energy consumption measurement and billing

- HVAC Optimization: Chilled water and heating system efficiency monitoring

- Energy Benchmarking: Building energy performance comparison and optimization

- Peak Demand Management: Demand response and peak shaving strategies

- Green Building Certification: LEED and BREEAM compliance monitoring

Healthcare Facilities

Hospital and healthcare facility BTU monitoring addressing critical environment control, regulatory compliance, and energy efficiency requirements. Healthcare applications ensure patient comfort while optimizing energy consumption.

Healthcare Applications

- Critical Area Monitoring: Operating room and ICU environmental control

- Sterilization Systems: Steam sterilization energy monitoring and validation

- Laboratory HVAC: Research laboratory environmental control and monitoring

- Patient Comfort: Patient room temperature and humidity optimization

- Regulatory Compliance: Joint Commission and regulatory requirement compliance

Educational Institutions

University and school BTU monitoring for campus energy management, academic building efficiency, and sustainability education. Educational applications support both operational efficiency and academic programs.

Educational Applications

- Campus Energy Management: Multi-building energy monitoring and optimization

- Dormitory Sub-Metering: Student housing energy consumption tracking

- Research Facility Monitoring: Laboratory and research building energy management

- Sustainability Programs: Student sustainability education and engagement

- Budget Management: Energy cost allocation and budget planning

Industrial Manufacturing

Industrial BTU monitoring for process heating, cooling, and steam systems supporting production efficiency and energy cost management. Manufacturing applications focus on process optimization and cost reduction.

Industrial Applications

- Process Heating: Industrial furnace and heating system energy monitoring

- Steam Systems: Steam generation and distribution efficiency tracking

- Process Cooling: Industrial cooling system energy consumption monitoring

- Production Optimization: Energy-intensive process optimization and control

- Utility Management: Steam, hot water, and chilled water utility monitoring

Data Centers

Data center BTU monitoring for cooling system efficiency, PUE calculation, and thermal management optimization. Data center applications focus on cooling efficiency and environmental sustainability.

Data Center Applications

- Cooling Efficiency: CRAC and chiller system efficiency monitoring

- PUE Calculation: Power Usage Effectiveness calculation and optimization

- Hot Aisle Monitoring: Server rack thermal management and optimization

- Free Cooling: Economizer and free cooling system optimization

- Capacity Planning: Thermal capacity planning and expansion analysis

Looking for industry-specific BTU monitoring solutions? Contact our industry experts to discuss BTU monitoring applications tailored to your specific industry requirements and operational challenges.

BTU Monitoring System Implementation and Integration Services

Comprehensive BTU monitoring implementation services including system design, sensor installation, calibration, commissioning, and ongoing support. Professional implementation ensures accurate measurement, reliable operation, and seamless integration with existing systems.

System Design and Engineering

Custom BTU monitoring system design including sensor selection, placement optimization, and integration planning. Engineering services ensure optimal measurement accuracy and system performance for specific applications.

Design Services

- Application Analysis: Detailed analysis of measurement requirements and objectives

- Sensor Selection: Optimal sensor specification for accuracy and reliability

- Installation Planning: Sensor placement and installation method optimization

- System Architecture: Communication network and data management design

- Integration Planning: BMS and enterprise system integration design

Installation and Commissioning

Professional installation and commissioning services including sensor installation, system configuration, calibration, and performance verification. Installation ensures proper system operation and measurement accuracy.

Installation Services

- Sensor Installation: Professional sensor mounting and connection

- System Configuration: DAVAS® platform setup and configuration

- Calibration Services: Sensor calibration and accuracy verification

- Performance Testing: System testing and performance validation

- Documentation: As-built documentation and user training

Integration and Connectivity

Seamless integration with building management systems, energy management platforms, and enterprise software through standard protocols and APIs. Integration enables centralized monitoring and coordinated control.

Integration Capabilities

- BMS Integration: Direct integration with building management systems

- Protocol Support: BACnet, Modbus, Ethernet/IP communication protocols

- API Development: Custom API development for specialized applications

- Cloud Integration: Secure cloud connectivity for remote monitoring

- Mobile Access: Mobile applications for remote system access

Ongoing Support and Maintenance

Comprehensive support services including system monitoring, calibration verification, troubleshooting, and optimization. Ongoing support ensures continued accuracy and system performance throughout the lifecycle.

Support Services

- Remote Monitoring: 24/7 system monitoring and performance analysis

- Calibration Verification: Periodic calibration verification and adjustment

- Technical Support: Expert troubleshooting and problem resolution

- System Optimization: Continuous improvement and performance enhancement

- Training Updates: Ongoing training for new features and capabilities

Need implementation support for your BTU monitoring project? Contact our implementation team to discuss your project requirements and develop a comprehensive deployment plan.

BTU Monitoring Standards and Energy Efficiency Compliance

BTU monitoring systems comply with industry standards and energy efficiency regulations ensuring accurate measurement, reliable operation, and regulatory compliance. Standards compliance provides confidence in measurement accuracy and supports energy efficiency initiatives.

Measurement Standards

Professional BTU monitoring follows established measurement standards ensuring accuracy, repeatability, and traceability. Standards compliance provides confidence in energy data and supports regulatory reporting requirements.

Industry Standards

- ASHRAE 90.1: Energy Standard for Buildings requirements for energy monitoring

- ANSI/ASME MFC-2M: Measurement uncertainty for flowmeters and flow measurement

- ISO 50001: Energy Management Systems standards and requirements

- IEC 62053: Electricity metering equipment standards and accuracy classes

- NIST Traceability: Calibration traceability to national standards

Energy Efficiency Regulations

BTU monitoring supports compliance with energy efficiency regulations and building codes requiring energy measurement and reporting. Regulatory compliance ensures legal adherence and supports energy efficiency initiatives.

Regulatory Requirements

- ASHRAE 90.1: Building energy efficiency requirements and monitoring

- Local Energy Codes: Municipal energy efficiency and reporting requirements

- Green Building Standards: LEED, BREEAM, and other certification requirements

- Utility Regulations: Energy reporting and demand response requirements

- Government Mandates: Federal and state energy efficiency mandates

Calibration and Verification

Regular calibration and verification procedures ensure continued measurement accuracy and standards compliance. Calibration services maintain traceability to national standards and support regulatory requirements.

Calibration Services

- Initial Calibration: Factory and field calibration with certified standards

- Periodic Verification: Regular calibration verification and adjustment

- Traceability Documentation: Calibration certificates and traceability records

- Accuracy Validation: Field accuracy testing and verification procedures

- Compliance Reporting: Calibration and compliance documentation

Need guidance on standards compliance and calibration? Contact our standards specialists to discuss compliance requirements and calibration services for your BTU monitoring system.

BTU Monitoring Return on Investment and Energy Savings

BTU monitoring investments deliver measurable returns through energy cost reduction, operational efficiency improvements, and equipment optimization. ROI analysis includes energy savings quantification, maintenance cost reduction, and productivity improvements from enhanced energy management.

Energy Cost Savings

Significant energy cost savings achieved through consumption optimization, efficiency improvements, and demand management. Cost savings result from identifying inefficiencies, optimizing operations, and implementing targeted improvements.

Cost Savings Opportunities

- Equipment Optimization: HVAC system efficiency improvements and optimization

- Peak Demand Reduction: Demand management and peak shaving strategies

- Operational Efficiency: Process optimization and energy waste elimination

- Maintenance Optimization: Predictive maintenance reducing energy waste

- Utility Incentives: Utility rebates and incentives for energy efficiency

Operational Benefits

Operational improvements through enhanced visibility, automated monitoring, and data-driven decision making. Operational benefits include improved system reliability, reduced maintenance costs, and enhanced comfort control.

Operational Improvements

- System Reliability: Improved equipment reliability through monitoring

- Maintenance Efficiency: Predictive maintenance reducing costs and downtime

- Comfort Control: Enhanced environmental control and occupant comfort

- Decision Support: Data-driven decisions for energy management

- Automated Control: Automatic optimization reducing manual intervention

Financial Analysis

Comprehensive financial analysis including payback calculations, ROI projections, and lifecycle cost analysis. Financial modeling demonstrates investment value and supports capital budgeting decisions.

Financial Metrics

- Payback Period: Typical payback of 1-3 years for BTU monitoring systems

- ROI Calculation: Return on investment analysis and projections

- Lifecycle Costs: Total cost of ownership including maintenance and support

- Energy Savings: Quantified energy savings and cost reductions

- Incentive Analysis: Utility and government incentive opportunities

Want to calculate ROI for your BTU monitoring investment? Contact our ROI specialists to receive a customized financial analysis and energy savings projection for your facility.

Professional BTU Monitoring Commitment

3Phase Tech Services provides comprehensive BTU monitoring solutions that deliver accurate energy measurement and measurable operational improvements. Our energy management specialists utilize proven DAVAS® platform technology and industry best practices to ensure successful energy monitoring implementations with maximum return on investment.

We understand that energy management requires precise measurement, reliable systems, and ongoing support to achieve efficiency objectives. Our BTU monitoring solutions are designed to provide accurate energy data while minimizing installation complexity and maximizing operational benefits.

Quality Assurance Program

Our quality assurance program includes sensor calibration, system testing, performance verification, and ongoing monitoring to ensure reliable operation and continued accuracy throughout the BTU monitoring system lifecycle.

Continuous Innovation

We continuously update our BTU monitoring capabilities, sensor technologies, and analytics platforms to incorporate the latest energy management advances and measurement best practices for optimal client results.

Ready to implement BTU monitoring for your facility? Contact our BTU monitoring specialists to discuss your energy management objectives and develop a comprehensive DAVAS® BTU monitoring solution that delivers accurate measurement and measurable energy savings.