DAVAS® Asset Health Monitoring

DAVAS® Asset Health Monitoring provides comprehensive condition monitoring and predictive maintenance solutions for industrial equipment and critical assets. Advanced monitoring systems utilize multiple sensor technologies, machine learning analytics, and automated diagnostics to prevent equipment failures, optimize maintenance schedules, and maximize asset reliability.

Send Enquiry

Common Issues in Industrial Machinery

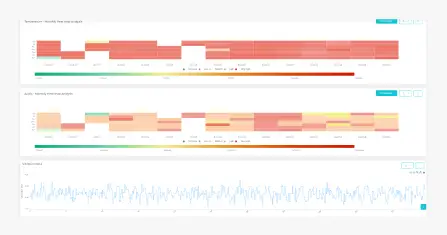

Machine Health Matrix Monitoring

Skin Temperature Monitoring

Acoustics Monitoring

RPM Monitoring

Vibration Monitoring

Asset Utilization Matrix

Idle Time Reduction

Energy Efficiency

Automated Control

Operational Savings

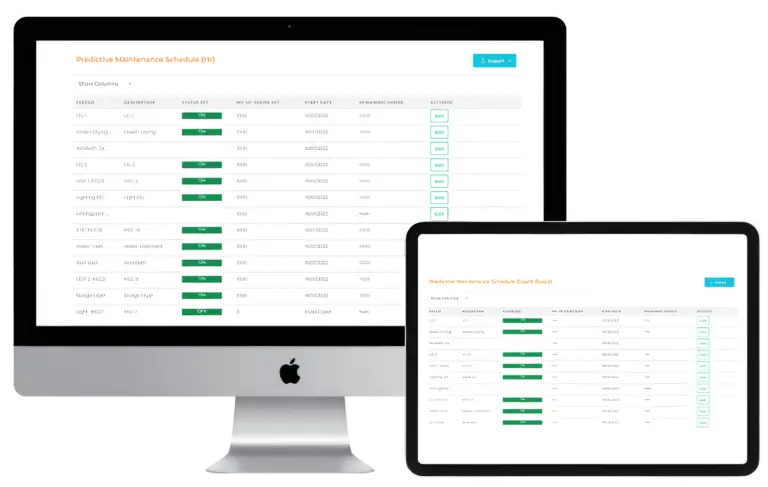

Predictive Maintenance Tool

DAVAS® Predictive Maintenance Tool provides comprehensive predictive analytics, maintenance optimization, and operational intelligence for industrial equipment. Advanced predictive tools utilize machine learning algorithms, condition monitoring data, and maintenance history to optimize maintenance schedules and prevent equipment failures.

Smart Scheduling

Intelligent maintenance scheduling based on equipment condition, operational requirements, and resource availability. Smart scheduling optimizes maintenance timing for minimal production impact and maximum equipment reliability.

Maintenance Optimization

Comprehensive maintenance optimization through data analytics, cost analysis, and performance tracking. Optimization includes maintenance strategy selection, spare parts management, and resource allocation for maximum efficiency.

Efficiency Enhancement

Maintenance efficiency enhancement through process optimization, technology integration, and performance measurement. Efficiency improvements reduce maintenance costs while improving equipment reliability and availability.

Operational Intelligence

Advanced operational intelligence through data analytics, machine learning, and predictive modeling. Intelligence capabilities provide insights for strategic decision-making and operational optimization.

Benefits

Enhanced Troubleshooting

Quickly identify the root causes of recurring issues with detailed data analysis and effective solution validation. Enhanced troubleshooting capabilities through comprehensive data collection, advanced analytics, and expert system diagnostics. Troubleshooting improvements reduce mean time to repair (MTTR) and improve first-time fix rates through better fault isolation and diagnosis.

Downtime Prevention

With round-the-clock monitoring, DAVAS® ensures potential issues are detected before they grow into costly failures. Comprehensive downtime prevention through continuous monitoring, early fault detection, and proactive maintenance intervention. Downtime prevention reduces unplanned outages and maintenance costs while improving equipment availability and production efficiency.

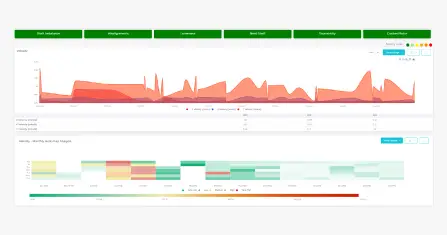

Operational Insights

Access automatically generated reports and visual dashboards that deliver valuable insights for informed decision-making. Benchmarking tools help evaluate performance trends over time. Comprehensive operational insights through automated reporting, performance dashboards, and advanced analytics. Insights enable data-driven decision-making for maintenance optimization, asset management, and operational improvement.

Energy Management

Monitor energy consumption continuously for better resource planning, sustainability improvements, and significant operational cost savings. Integrated energy management capabilities through power monitoring, efficiency analysis, and optimization recommendations. Energy management reduces operational costs while supporting sustainability initiatives and regulatory compliance.

Frequently Asked Questions

What is asset health monitoring?

Asset health monitoring is a comprehensive system that continuously tracks equipment condition using sensors and analytics to detect performance degradation, predict failures, and optimize maintenance schedules. It includes vibration analysis, thermal monitoring, oil analysis, and other condition monitoring techniques.

Asset health monitoring provides real-time condition assessment, trend analysis, fault detection, and predictive maintenance recommendations enabling proactive maintenance and improved equipment reliability.

How does predictive maintenance reduce costs?

Predictive maintenance reduces costs by preventing unexpected failures, optimizing maintenance schedules, reducing spare parts inventory, and extending equipment life. Typical cost savings range from 20-40% compared to reactive maintenance approaches.

Cost reductions result from reduced emergency repairs, optimized maintenance intervals, improved labor efficiency, and eliminated unnecessary maintenance activities.

What sensors are used for asset health monitoring?

Asset health monitoring uses vibration sensors, temperature sensors, current sensors, pressure transducers, acoustic sensors, and oil analysis sensors. Sensor selection depends on equipment type, operating conditions, and failure modes being monitored.

Multiple sensor types are often combined to provide comprehensive condition monitoring coverage addressing different failure modes and monitoring requirements.

How accurate is predictive maintenance?

Modern predictive maintenance systems achieve 85-95% accuracy in failure prediction when properly implemented with appropriate sensors and analytics. Accuracy depends on data quality, sensor placement, and machine learning algorithm training.

Accuracy improves over time as machine learning algorithms learn from historical data and failure patterns specific to the monitored equipment.

How long does asset health monitoring implementation take?

Implementation typically requires 2-6 months depending on system complexity and equipment coverage. Implementation includes program development, sensor installation, system commissioning, and training phases.

What maintenance strategies work with condition monitoring?

Condition monitoring supports predictive maintenance, condition-based maintenance, and reliability-centered maintenance strategies. It optimizes maintenance timing based on actual equipment condition rather than fixed schedules.

Can asset health monitoring integrate with existing systems?

Yes, DAVAS® asset health monitoring integrates with CMMS, ERP, and plant control systems through standard protocols and APIs enabling centralized maintenance management and workflow automation.

What training is required for asset health monitoring?

Training includes system operation, data interpretation, alarm management, and basic diagnostics for operators. Advanced training covers vibration analysis, thermography, and predictive maintenance for specialists.

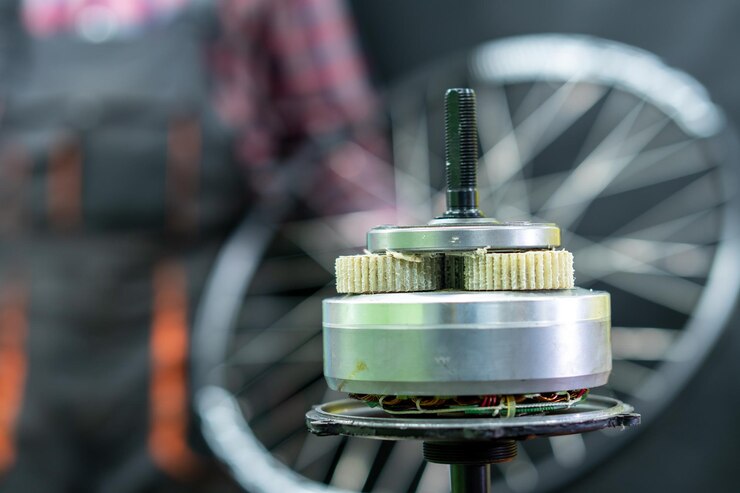

Mechanical Failure Modes

Mechanical failures represent the majority of industrial equipment problems including bearing degradation, gear wear, coupling misalignment, and shaft imbalance. Mechanical condition monitoring utilizes vibration analysis, thermal monitoring, and oil analysis to detect developing faults.

Common Mechanical Issues

- Bearing Failures: Rolling element fatigue, inadequate lubrication, and contamination

- Gear Problems: Tooth wear, pitting, scoring, and lubrication breakdown

- Misalignment: Angular and parallel misalignment causing premature wear

- Imbalance: Mass imbalance creating excessive vibration and bearing stress

- Looseness: Mechanical looseness in foundations, bolts, and couplings

Electrical System Failures

Electrical failures including motor winding degradation, insulation breakdown, and power quality issues significantly impact equipment reliability. Electrical condition monitoring utilizes current signature analysis, insulation testing, and power quality monitoring.

Electrical Failure Modes

- Insulation Degradation: Winding insulation deterioration from heat and moisture

- Rotor Bar Defects: Broken rotor bars and end ring failures in induction motors

- Stator Winding Faults: Turn-to-turn faults and phase imbalance issues

- Connection Problems: Loose connections and contact resistance increases

- Power Quality Issues: Voltage unbalance, harmonics, and power factor problems

Lubrication and Contamination Issues

Lubrication failures and contamination account for significant equipment problems including inadequate lubrication, contamination ingress, and lubricant degradation. Oil analysis and contamination monitoring provide early detection of lubrication issues.

Lubrication Problems

- Inadequate Lubrication: Insufficient lubricant quantity or incorrect specifications

- Contamination: Water, particles, and chemical contamination in lubricants

- Lubricant Degradation: Oxidation, thermal breakdown, and additive depletion

- Seal Failures: Shaft seal failures allowing contamination and lubricant loss

- Over-Lubrication: Excessive lubrication causing churning and overheating

Need help identifying equipment failure modes? Contact our condition monitoring experts to discuss equipment-specific failure modes and appropriate monitoring strategies for your critical assets.

Machine Health Matrix Monitoring

Machine Health Matrix Monitoring provides comprehensive multi-parameter condition assessment using vibration, temperature, current, and pressure monitoring. Matrix monitoring enables correlation analysis, fault isolation, and comprehensive equipment health assessment for reliable predictive maintenance.

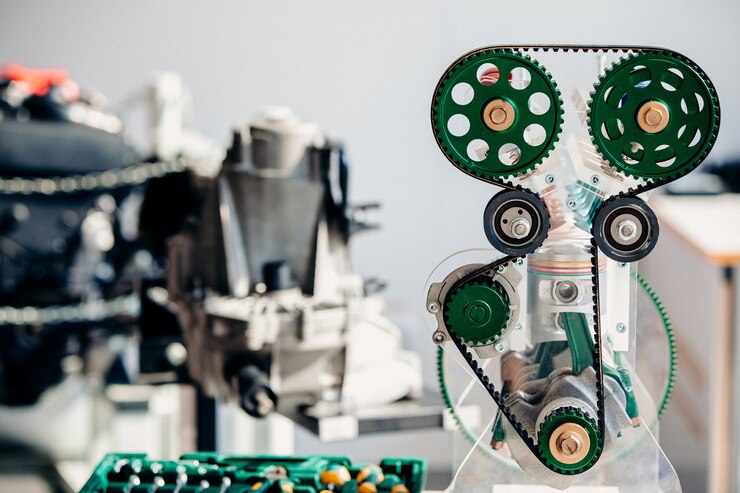

Vibration Monitoring and Analysis

Vibration monitoring forms the foundation of mechanical condition monitoring providing early detection of bearing faults, imbalance, misalignment, and mechanical looseness. Advanced vibration analysis includes time domain, frequency domain, and envelope analysis techniques.

Vibration Monitoring Features

- Accelerometer Sensors: High-frequency vibration measurement with ±1% accuracy

- Frequency Analysis: FFT analysis identifying fault frequencies and harmonics

- Envelope Analysis: Bearing fault detection through envelope demodulation

- Trend Monitoring: Long-term vibration trending and alarm management

- Route-Based Monitoring: Portable and fixed-point vibration monitoring

Thermal Monitoring and Thermography

Thermal monitoring detects equipment overheating, electrical faults, and lubrication problems through continuous temperature measurement and infrared thermography. Thermal analysis provides early warning of developing thermal issues.

Thermal Monitoring Capabilities

- RTD Temperature Sensors: Precision temperature measurement with ±0.1°C accuracy

- Infrared Thermography: Non-contact thermal imaging and hot spot detection

- Thermal Trending: Long-term temperature trending and alarm systems

- Thermal Imaging: Periodic thermal imaging surveys and analysis

- Heat Balance Analysis: Equipment thermal efficiency and heat transfer analysis

Electrical Current Monitoring

Motor current signature analysis (MCSA) provides non-intrusive monitoring of electrical machine health detecting rotor bar defects, air gap eccentricity, and stator winding faults. Current monitoring enables electrical fault detection without equipment shutdown.

Current Monitoring Features

- Current Signature Analysis: MCSA for electrical fault detection and analysis

- Power Quality Monitoring: Voltage unbalance, harmonics, and power factor analysis

- Starting Current Analysis: Motor starting characteristics and fault detection

- Load Analysis: Motor loading and efficiency analysis

- Trend Monitoring: Electrical parameter trending and alarm management

Pressure and Flow Monitoring

Pressure and flow monitoring provides hydraulic and pneumatic system condition assessment detecting pump degradation, valve problems, and system leakage. Pressure monitoring enables early detection of hydraulic system issues.

Pressure Monitoring Applications

- Pump Condition Monitoring: Pump performance and cavitation detection

- Hydraulic System Analysis: System pressure, flow, and efficiency monitoring

- Valve Performance: Control valve positioning and leakage detection

- System Leakage: Hydraulic and pneumatic system leakage detection

- Filter Monitoring: Filter differential pressure and replacement indicators

Interested in comprehensive health matrix monitoring? Contact our monitoring engineers to design a multi-parameter monitoring system tailored to your equipment requirements and operational needs.

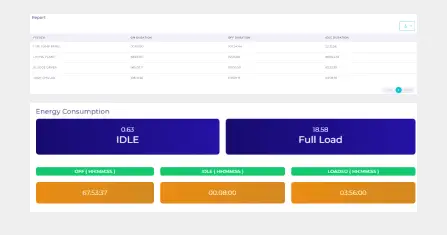

Asset Utilization Matrix

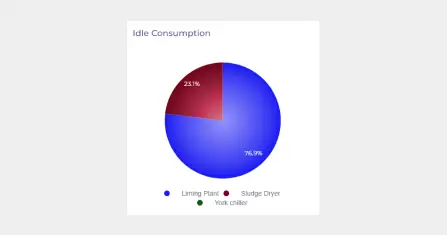

Idle Time Reduction

Idle time reduction through continuous asset utilization monitoring and optimization. Utilization analysis identifies equipment downtime causes, scheduling inefficiencies, and operational bottlenecks enabling improved asset productivity and return on investment.

Idle Time Optimization Features

- Utilization Tracking: Real-time equipment utilization and idle time monitoring

- Downtime Analysis: Automated downtime categorization and root cause analysis

- Scheduling Optimization: Production scheduling optimization for maximum utilization

- Bottleneck Identification: Production bottleneck identification and elimination

- Performance Benchmarking: Asset performance comparison and benchmarking

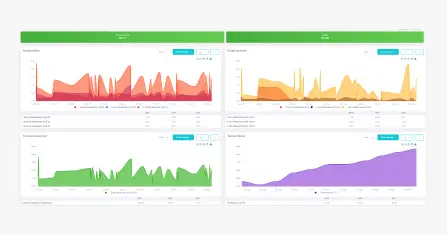

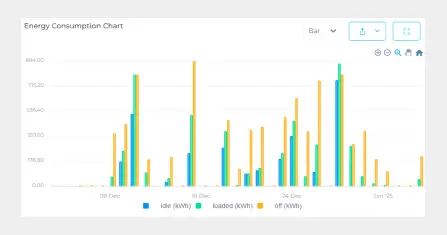

Energy Efficiency

Energy efficiency monitoring and optimization through continuous power consumption analysis, load profiling, and efficiency trending. Energy analysis identifies opportunities for consumption reduction and operational cost savings.

Energy Efficiency Features

- Power Monitoring: Real-time electrical power consumption monitoring

- Efficiency Trending: Equipment efficiency trending and performance analysis

- Load Profiling: Equipment load profiling and optimization opportunities

- Energy Benchmarking: Energy consumption benchmarking and comparison

- Cost Analysis: Energy cost analysis and optimization recommendations

Automated Control

Automated control systems optimize equipment operation through intelligent algorithms, predictive control, and adaptive optimization. Automated systems reduce operator workload while improving consistency and efficiency.

Automated Control Capabilities

- Predictive Control: Model predictive control for optimal equipment operation

- Adaptive Algorithms: Self-learning algorithms adapting to changing conditions

- Optimization Routines: Automated optimization routines for peak performance

- Safety Interlocks: Automated safety systems and emergency shutdown

- Remote Control: Remote monitoring and control capabilities

Operational Savings

Operational savings quantification through comprehensive cost analysis, maintenance optimization, and productivity improvements. Savings analysis provides ROI justification and continuous improvement opportunities.

Savings Quantification

- Maintenance Cost Reduction: Predictive maintenance cost savings analysis

- Production Optimization: Production efficiency improvements and cost savings

- Energy Savings: Energy consumption reduction and cost benefits

- Quality Improvements: Product quality improvements and waste reduction

- Inventory Optimization: Spare parts inventory optimization and cost reduction

Want to optimize your asset utilization? Contact our utilization experts to analyze your current asset performance and develop optimization strategies for improved productivity and cost savings.

Advanced Condition Monitoring Technologies and Techniques

Asset health monitoring utilizes multiple condition monitoring technologies providing comprehensive equipment assessment and fault detection. Advanced technologies include vibration analysis, thermal monitoring, oil analysis, ultrasonic testing, and electrical signature analysis.

Vibration Analysis and Diagnostics

Vibration analysis provides the most comprehensive mechanical condition monitoring capability detecting bearing faults, imbalance, misalignment, looseness, and gear problems. Advanced vibration diagnostics include spectral analysis, envelope analysis, and order tracking.

Vibration Analysis Techniques

- Time Domain Analysis: RMS, peak, crest factor, and kurtosis analysis

- Frequency Domain Analysis: FFT spectral analysis and fault frequency identification

- Envelope Analysis: High-frequency demodulation for bearing fault detection

- Order Tracking: Order-based analysis for variable speed equipment

- Modal Analysis: Operating deflection shape and resonance analysis

Thermal Monitoring and Thermography

Thermal monitoring detects overheating conditions, electrical faults, and lubrication problems through continuous temperature measurement and periodic infrared thermography surveys.

Thermal Monitoring Methods

- Contact Temperature Measurement: RTD and thermocouple temperature monitoring

- Infrared Thermography: Non-contact thermal imaging and analysis

- Thermal Trending: Long-term temperature trending and alarm management

- Hot Spot Detection: Automated hot spot detection and alerting

- Thermal Efficiency Analysis: Equipment thermal efficiency assessment

Oil Analysis and Tribology

Oil analysis provides comprehensive lubrication condition monitoring detecting wear particles, contamination, and lubricant degradation. Tribological analysis enables early detection of lubrication-related problems.

Oil Analysis Parameters

- Wear Metal Analysis: Spectrometric analysis of wear metals and contaminants

- Particle Counting: Particle size distribution and contamination levels

- Water Content: Water contamination detection and quantification

- Acid Number: Lubricant oxidation and degradation assessment

- Viscosity Analysis: Lubricant viscosity and shear stability testing

Ultrasonic Testing and Analysis

Ultrasonic monitoring detects mechanical faults, electrical problems, and leakage through high-frequency acoustic analysis. Ultrasonic testing provides early detection of developing faults not detectable by other methods.

Ultrasonic Applications

- Bearing Condition Monitoring: High-frequency bearing condition assessment

- Electrical Fault Detection: Corona, arcing, and tracking detection

- Leak Detection: Compressed air, steam, and vacuum leak detection

- Valve Testing: Valve leak-by and operation verification

- Steam Trap Monitoring: Steam trap operation and failure detection

Need guidance on condition monitoring technology selection? Contact our technology specialists to discuss appropriate monitoring technologies for your specific equipment and application requirements.

Asset Health Monitoring Implementation Services

Comprehensive implementation services including condition monitoring program development, sensor installation, system commissioning, and training. Professional implementation ensures optimal monitoring effectiveness and maximum return on investment.

Condition Monitoring Program Development

Custom condition monitoring program development including equipment criticality analysis, monitoring strategy selection, and implementation planning. Program development ensures comprehensive coverage of critical assets and cost-effective monitoring approaches.

Program Development Services

- Criticality Analysis: Equipment criticality assessment and priority ranking

- Strategy Selection: Monitoring strategy selection based on failure modes

- Technology Selection: Appropriate monitoring technology selection and specification

- Implementation Planning: Phased implementation planning and resource allocation

- ROI Analysis: Return on investment analysis and business case development

System Design and Engineering

Custom monitoring system design including sensor selection, installation specifications, and data management architecture. Engineering services ensure optimal system performance and integration with existing infrastructure.

Design Services

- Sensor Selection: Optimal sensor specification for monitoring requirements

- Installation Design: Sensor mounting and installation specification

- Data Architecture: Data collection and management system design

- Communication Networks: Wireless and wired communication system design

- Integration Planning: CMMS and enterprise system integration design

Installation and Commissioning

Professional installation and commissioning services including sensor mounting, system configuration, baseline establishment, and performance verification. Installation ensures proper system operation and measurement accuracy.

Installation Services

- Sensor Installation: Professional sensor mounting and connection

- System Configuration: DAVAS® platform setup and configuration

- Baseline Establishment: Equipment baseline data collection and analysis

- Performance Verification: System testing and performance validation

- Training Delivery: Comprehensive operator and analyst training

Ongoing Support and Optimization

Continuous support services including performance monitoring, system optimization, and program enhancement. Ongoing support ensures continued effectiveness and adaptation to changing requirements.

Support Services

- Performance Monitoring: Continuous system performance monitoring and analysis

- Program Optimization: Monitoring program optimization and enhancement

- Technical Support: Expert technical support and troubleshooting

- Training Updates: Ongoing training and competency development

- Technology Updates: System updates and technology upgrades

Need implementation support for your monitoring program? Contact our implementation team to discuss your project requirements and develop a comprehensive deployment plan.

Industry-Specific Asset Health Monitoring Applications

Asset health monitoring serves diverse industries with unique equipment types, operational challenges, and reliability requirements. Industry-specific applications leverage condition monitoring technologies for equipment optimization and maintenance cost reduction.

Manufacturing and Process Industries

Manufacturing asset health monitoring including rotating equipment, process machinery, and production systems. Manufacturing applications focus on production continuity, quality consistency, and operational efficiency.

Manufacturing Applications

- Rotating Equipment: Motors, pumps, compressors, and fan monitoring

- Production Machinery: CNC machines, presses, and automated equipment

- Process Equipment: Heat exchangers, reactors, and processing vessels

- Material Handling: Conveyors, cranes, and transportation systems

- Utility Systems: Compressed air, steam, and cooling water systems

Oil and Gas Industry

Oil and gas asset monitoring including drilling equipment, production systems, pipeline infrastructure, and refinery equipment. Applications address remote location challenges and safety requirements.

Oil and Gas Applications

- Drilling Equipment: Mud pumps, drawworks, and rotary equipment

- Production Systems: Wellhead equipment, separators, and processing units

- Pipeline Infrastructure: Compressor stations and pipeline monitoring

- Refinery Equipment: Rotating machinery and process equipment monitoring

- Offshore Platforms: Critical equipment monitoring in harsh environments

Power Generation

Power generation asset monitoring including turbines, generators, auxiliaries, and balance-of-plant equipment. Power applications require high reliability and availability for grid stability.

Power Generation Applications

- Steam Turbines: Turbine rotor monitoring and blade condition assessment

- Gas Turbines: Compressor, combustor, and turbine monitoring

- Generators: Generator rotor and stator condition monitoring

- Auxiliary Equipment: Boiler feed pumps, cooling systems, and fans

- Renewable Energy: Wind turbine and solar tracking system monitoring

Mining and Metals

Mining asset health monitoring including extraction equipment, processing machinery, and material handling systems. Mining applications address harsh operating conditions and remote locations.

Mining Applications

- Extraction Equipment: Draglines, shovels, and underground equipment

- Processing Equipment: Crushers, mills, and separation equipment

- Material Handling: Conveyor systems and stacker-reclaimers

- Mobile Equipment: Haul trucks, loaders, and mobile machinery

- Processing Plants: Concentrator and smelter equipment monitoring

Looking for industry-specific monitoring solutions? Contact our industry experts to discuss asset health monitoring applications tailored to your specific industry requirements and operational challenges.

Asset Health Monitoring ROI and Business Benefits

Asset health monitoring delivers substantial return on investment through maintenance cost reduction, downtime prevention, and operational efficiency improvements. ROI analysis includes maintenance savings, production benefits, and asset life extension.

Maintenance Cost Reduction

Significant maintenance cost reductions achieved through predictive maintenance, optimized scheduling, and reduced emergency repairs. Cost reductions typically range from 20-40% compared to reactive maintenance approaches.

Cost Reduction Areas

- Preventive Maintenance Optimization: 15-25% reduction in preventive maintenance costs

- Emergency Repair Elimination: 50-80% reduction in emergency maintenance events

- Spare Parts Optimization: 20-30% reduction in spare parts inventory costs

- Labor Efficiency: 25-35% improvement in maintenance labor productivity

- Contractor Costs: Reduced external contractor and overtime costs

Production and Availability Benefits

Production benefits through reduced unplanned downtime, improved equipment reliability, and optimized maintenance scheduling. Production improvements enhance revenue and operational efficiency.

Production Improvements

- Availability Improvement: 2-5% improvement in equipment availability

- Downtime Reduction: 40-70% reduction in unplanned downtime events

- Quality Improvement: Reduced product quality issues from equipment problems

- Production Scheduling: Improved production planning and scheduling flexibility

- Asset Utilization: Enhanced asset utilization and productivity

Financial Analysis and ROI

Comprehensive financial analysis including implementation costs, operational savings, and payback calculations. Typical ROI for asset health monitoring ranges from 200-500% annually.

Financial Metrics

- Payback Period: Typical payback of 6-18 months for monitoring systems

- Annual ROI: 200-500% annual return on monitoring investment

- Lifecycle Benefits: Continued benefits throughout 10-15 year asset life

- Risk Mitigation: Reduced financial risk from catastrophic failures

- Asset Value: Enhanced asset value through improved condition management

Want to calculate ROI for your monitoring program? Contact our ROI specialists to receive a customized financial analysis and return on investment projection for your asset health monitoring implementation.

Professional Asset Health Monitoring Commitment

3Phase Tech Services provides comprehensive asset health monitoring solutions that deliver measurable reliability improvements and maintenance cost reductions. Our condition monitoring specialists utilize proven DAVAS® technology and industry best practices to ensure successful monitoring implementations with maximum return on investment.

We understand that effective asset health monitoring requires proper technology selection, professional implementation, and ongoing optimization to achieve reliability objectives. Our monitoring solutions are designed to provide comprehensive equipment oversight while delivering immediate maintenance benefits and long-term asset optimization.

Quality Assurance Program

Our quality assurance program includes sensor calibration, system testing, baseline validation, and ongoing performance monitoring to ensure reliable operation and accurate condition assessment throughout the monitoring system lifecycle.

Continuous Innovation

We continuously update our monitoring capabilities, sensor technologies, and analytics algorithms to incorporate the latest condition monitoring advances and predictive maintenance best practices for optimal client results.

Ready to implement comprehensive asset health monitoring? Contact our asset health specialists to discuss your equipment monitoring requirements and develop a customized DAVAS® solution that delivers reliable condition monitoring and measurable maintenance improvements.