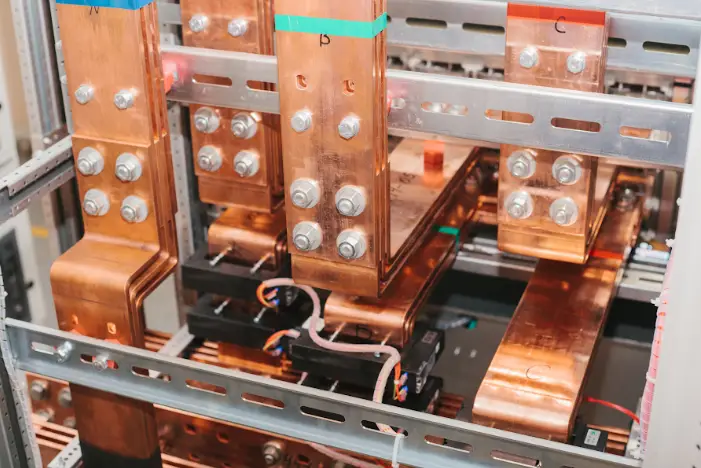

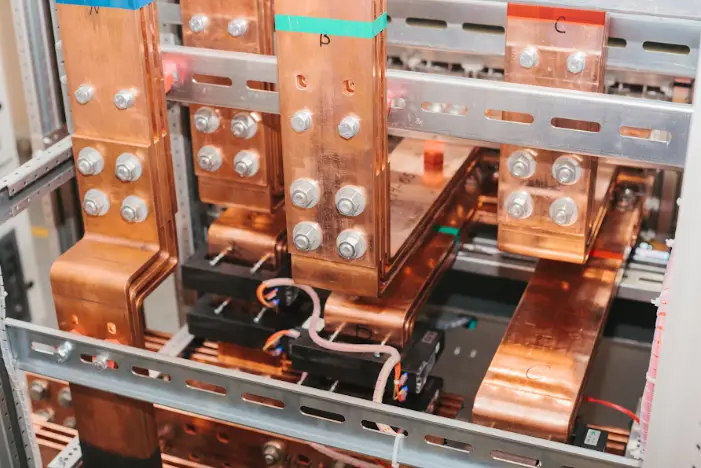

DAVAS® Busbar Temperature Monitoring & Control Solution

DAVAS® provides accurate and continuous monitoring of electrical busbar systems, identifying abnormal temperature variations before they become critical. This proactive approach reduces the likelihood of equipment damage, prevents operational downtime, and strengthens electrical safety while ensuring stable power distribution across all connected systems.

Send Enquiry

The Risks of Rising Busbar Temperatures

System Failures

Excessive heat weakens busbars over time, leading to sudden breakdowns that disrupt operations.

Equipment Damage

Overheating impacts connected electrical devices, resulting in costly repairs or replacements.

Fire Hazards

High temperatures increase the risk of electrical fires, endangering both assets and personnel.

Reputation Risks

Incidents caused by system failures or fires can negatively affect trust and business credibility.

Power Outages

Temperature spikes can trigger outages that halt production and cause financial setbacks.

Regulatory Issues

Overheated systems may lead to compliance violations, attracting fines and additional inspections.

Efficiency Losses

Persistent overheating lowers system efficiency and increases operational costs.

Key Features

Wireless Real-Time Monitoring

Automatic Overheat Protection

Historical Data Analysis

Seamless Integration

Energy-Efficient Design

Smart Reporting & Instant Alerts

Benefits

Stronger Safety Measures

Helps prevent electrical fires by keeping busbar temperatures under control at all times.

Planned Maintenance

Early detection of potential issues allows maintenance to be scheduled in advance, reducing downtime.

Reliable Operations

Ensures uninterrupted system performance with real-time monitoring and automated protection.

Lower Operational Costs

Prevents unexpected failures, minimizes repair expenses, and extends equipment life for long-term savings.

Frequently Asked Questions

What types of temperature sensors are best for busbar monitoring?

Busbar temperature monitoring utilizes non-contact infrared, contact RTD, thermocouple, and fiber optic sensors. Non-contact infrared sensors provide safe measurement of energized equipment. Contact sensors deliver highest accuracy for critical monitoring points. Fiber optic sensors provide distributed measurement detecting hot spots. Sensor selection depends on measurement requirements, accuracy needs, and installation location.

How accurate are busbar temperature monitoring systems?

Professional busbar temperature monitoring systems achieve accuracy levels of ±0.5% to ±3% depending on sensor technology and installation quality. Contact sensors provide ±0.5% to ±1% accuracy. Non-contact infrared sensors achieve ±2% to ±3% for thermal profiling. Accuracy is maintained through proper sensor selection, professional installation, and periodic calibration verification.

Can busbar monitoring systems detect electrical problems?

Busbar temperature monitoring systems detect overheating from increased electrical resistance, loose connections causing localized heating, and transformer thermal issues. Rapid temperature increases indicate connection problems. Thermal imbalances across phases indicate phase current variations. Historical trending identifies gradual degradation requiring maintenance.

What is the difference between manual and automated temperature monitoring?

Manual temperature monitoring requires staff to physically measure busbar temperature using thermal cameras. Automated monitoring uses continuous sensors transmitting data to central platforms. Automated approaches eliminate labor while providing real-time visibility, historical trending, and immediate alerting for thermal issues.

How does wireless busbar temperature monitoring work?

Wireless monitoring uses battery-powered sensors transmitting thermal data via LoRa or Wi-Fi networks to cloud platforms. LoRa provides long-range communication up to several kilometers on low power. Wi-Fi connectivity utilizes existing facility networks. Data transmits at configurable intervals providing real-time thermal visibility.

What maintenance is required for temperature monitoring systems?

Maintenance includes periodic sensor calibration, battery replacement for wireless units, and system performance verification. Infrared sensors require lens cleaning and periodic calibration. Contact sensors need recalibration annually. Fiber optic sensors require connector cleaning. Professional maintenance ensures continued accuracy and system reliability.

Can busbar monitoring systems integrate with existing SCADA systems?

Busbar temperature monitoring systems integrate with SCADA, building management systems, and enterprise software through standard protocols including Modbus, Profibus, and BACnet. RESTful APIs enable custom application development. Integration creates unified electrical management platforms.

What ROI can be expected from busbar temperature monitoring?

Busbar temperature monitoring systems typically deliver 150-400% annual ROI through preventive maintenance, failure prevention, and reduced emergency repairs. Payback periods range 6-18 months for commercial and industrial applications. Savings result from prevented equipment failures, reduced downtime, and operational efficiency improvements.

Comprehensive Analysis of Traditional Busbar Temperature Monitoring Limitations

Traditional temperature measurement methods face significant limitations including coverage gaps, measurement inconsistencies, response delays, and maintenance challenges. Manual temperature checking and basic monitoring systems cannot provide the comprehensive thermal oversight required for modern electrical system operations.

Manual Temperature Measurement Challenges

Manual busbar temperature measurements using handheld thermal cameras and contact probes provide limited coverage, introduce human error, and cannot detect rapid temperature changes. Manual methods are labor-intensive, inconsistent, and inadequate for continuous monitoring requirements.

Coverage Limitations Limited measurement points and infrequent sampling missing temperature variations

Human Error Measurement inconsistencies and operator variability affecting data accuracy

Response Delays Days or weeks between temperature excursion occurrence and detection

Safety Risks Personnel exposure to energized electrical equipment during manual measurements

Labor Intensive High labor costs and resource requirements for periodic monitoring

Wired Sensor Limitations

Traditional wired temperature sensors face installation challenges, maintenance issues, and reliability problems including cable failures, connection degradation, and environmental damage. Wired systems require extensive infrastructure and ongoing maintenance.

Installation Complexity Extensive cabling and conduit installation requirements through electrical enclosures

Cable Failures Wire damage from environmental conditions and mechanical stress near equipment

Maintenance Issues Connector corrosion and connection degradation affecting signal integrity

Scalability Problems Difficult and expensive system expansion adding new monitoring points

Single Points of Failure Cable damage affecting multiple measurement points or entire monitoring circuits

Hidden Risk Factors

Traditional monitoring methods cannot detect developing thermal issues, intermittent problems, and gradual degradation patterns that lead to unexpected failures. Hidden risks accumulate over time creating catastrophic failure potential.

Gradual Degradation Slowly developing thermal issues not detected by periodic checks

Intermittent Problems Temperature excursions occurring between manual measurement intervals

Thermal Cycling Repeated heating and cooling cycles causing material fatigue and connection loosening

Hot Spots Localized overheating not detected by single-point measurements

Aging Equipment Deteriorating connections creating increasing resistance and heat generation

Ready to move beyond manual thermal inspection? Contact our busbar temperature specialists to discuss electrical system thermal monitoring needs and develop a customized DAVAS busbar monitoring solution.

DAVAS Busbar Temperature Monitoring Solution

Stay ahead of temperature changes and ensure your electrical equipment operates at peak efficiency. DAVAS Busbar Temperature Monitoring Solution provides comprehensive thermal management capabilities including real-time temperature measurement, automated control, alarm management, and data analytics. The platform integrates multiple sensor technologies with advanced control algorithms ensuring optimal thermal conditions and equipment protection.

How DAVAS Busbar Temperature Monitoring Works

Monitor

Capture real-time busbar temperature data across all electrical distribution points using DAVAS wireless sensors. Sensors continuously measure temperature and connection integrity transmitting data every 5-15 minutes providing complete thermal visibility of all busbars.

Visualize

Access readings on the DAVAS dashboard, presented in clear graphical formats for easy interpretation. Real-time displays show current temperatures, trend graphs, alarm status, and multi-location comparisons enabling quick assessment of busbar thermal conditions across entire electrical systems.

Action

Use accurate thermal data insights to make timely, informed operational decisions. Instant alerts via email, SMS, and mobile notifications enable immediate response to detected temperature excursions and thermal anomalies preventing equipment damage and electrical fires.

Transmit

Generate automatic reports with detailed thermal data visualization and analysis. Benchmarking features provide deeper insights into busbar thermal performance across multiple substations enabling identification of efficiency opportunities and maintenance priorities.

Analysis

Review historical temperature trends with detailed logs of thermal patterns and thermal events. Reports are available for download in both PDF and Excel formats supporting thermal analysis, operational planning, and compliance documentation requirements.

Professional Busbar Temperature Sensor Technologies and Specifications

Professional busbar temperature monitoring utilizes multiple sensor technologies optimized for different measurement requirements, accuracy specifications, and installation conditions. Sensor selection considers measurement range, accuracy specifications, response time, wireless connectivity, and power requirements.

Non-Contact Infrared Sensors

Non-contact infrared sensors measure busbar surface temperature without physical contact enabling safe measurement of energized electrical equipment. Infrared sensors provide fast response and long-term reliability without installation complexity.

Measurement Range -40°C to 200°C for standard electrical monitoring applications

Accuracy ±2% to ±3% of reading for thermal profiling and alarm functions

Response Time Millisecond response times enabling detection of rapid temperature changes

Non-Contact Measurement Safe measurement of energized busbars and electrical connections

Wireless Transmission Battery-powered sensors with LoRa or Wi-Fi connectivity

Contact Temperature Sensors

Contact temperature sensors mounted directly on busbars provide highest accuracy for critical monitoring points. RTD and thermocouple sensors deliver precision measurement suitable for thermal control applications.

Measurement Range -50°C to 150°C for typical busbar monitoring

Accuracy ±0.5% to ±1% for precise thermal measurement and control

Installation Direct mounting on busbar surfaces or within connection terminals

Response Time 1-5 seconds enabling detection of thermal variations

Wireless Connectivity Battery-powered sensors with extended range communication

Distributed Fiber Optic Sensors

Fiber optic temperature sensors provide distributed measurement along entire busbar lengths detecting hot spots and thermal variations. Optical technology eliminates electromagnetic interference common near electrical equipment.

Distributed Sensing Continuous temperature measurement along busbar length

Hot Spot Detection Millimeter-scale resolution detecting localized overheating

EMI Immunity Complete immunity to electromagnetic interference from electrical equipment

Safety Inherently safe measurement with no electrical connection to live equipment

Accuracy ±1°C measurement accuracy across monitoring length

Wireless Communication Technologies

DAVAS sensors utilize multiple wireless communication technologies optimized for different facility requirements including range, battery life, and infrastructure considerations.

LoRa Communication

Range 2-5 km outdoor, 200-500 meters indoor through electrical enclosures

Battery Life 3-5 years with 15-minute reporting intervals

Infrastructure Requires LoRaWAN gateway for network connectivity

Applications Substations, large electrical systems, outdoor equipment monitoring

Wi-Fi Communication

Range 30-100 meters depending on electrical enclosure construction

Battery Life 1-2 years with 15-minute reporting intervals

Infrastructure Utilizes existing facility networks

Applications Facilities with comprehensive wireless coverage

Need help selecting appropriate busbar temperature sensors? Contact our sensor specialists to discuss thermal monitoring requirements and receive recommendations for optimal sensor selection and specifications.

DAVAS Platform Features and Capabilities

Core Platform Capabilities

Real-Time Dashboards

Customizable real-time dashboards displaying current busbar temperatures, thermal trend graphs, alarm status, and key performance indicators. Dashboard widgets include temperature gauges, thermal trend charts, alarm lists, and facility maps showing all monitoring locations.

Cloud-Based Architecture

Secure cloud infrastructure providing reliable thermal data storage, automatic backups, and global accessibility. Cloud architecture eliminates local server requirements while ensuring data security and 24/7 availability for emergency response.

Multi-Location Monitoring

Simultaneous monitoring of unlimited electrical distribution locations, substations, and equipment from unified dashboards. Multi-location capabilities support distributed electrical systems with centralized management and standardized monitoring protocols.

Mobile Applications

Native iOS and Android mobile applications providing remote thermal monitoring, alert management, and report access. Mobile apps enable monitoring from anywhere with push notifications for critical temperature alerts and thermal events.

Integration Capabilities

RESTful APIs and standard protocols enable integration with building management systems, energy management platforms, SCADA systems, and enterprise software. Integration capabilities include:

SCADA Integration Modbus TCP, Profibus, and EthernetIP protocols for substation integration

Facility Management API connections with building and facility management systems

Billing Systems Data export to energy management and operational cost tracking systems

Maintenance Systems CMMS integration for thermal maintenance work orders

Data Export CSV, Excel, and database export capabilities

Advanced Analytics and Reporting

Analytics Features

Comprehensive analytics capabilities provide deep insights into busbar thermal performance, identify optimization opportunities, and support continuous improvement initiatives.

Trend Analysis Long-term thermal trending revealing seasonal patterns and thermal changes

Statistical Analysis Temperature statistics, peak analysis, and thermal distribution assessment

Benchmarking Performance comparison across substations and time periods

Thermal Correlation Temperature data correlated with load and operational activities

Predictive Analytics Machine learning identifying patterns and predicting thermal issues

Reporting Capabilities

Automated Reports Scheduled daily, weekly, or monthly thermal report generation

Custom Reports Configurable report templates for specific monitoring needs

Compliance Reports Regulatory reports with thermal monitoring documentation

Executive Summaries High-level thermal performance summaries for management review

Export Formats PDF and Excel export with custom formatting options

Interested in exploring platform capabilities? Contact our platform specialists to schedule a live demonstration of DAVAS busbar temperature monitoring features and discuss specific requirements.

Busbar Temperature Monitoring Implementation Services

Thermal System Assessment

Detailed electrical system assessment identifying busbar temperature monitoring requirements, critical thermal points, sensor placement locations, and coverage optimization. Assessment services provide implementation roadmap and system specifications.

Assessment Services

Facility Survey On-site evaluation of busbar systems and thermal monitoring requirements

Risk Assessment Identification of critical thermal points and overheating risk locations

Coverage Planning Temperature sensor quantity and placement recommendations

Wireless Planning RF survey and communication infrastructure optimization for substations

Integration Analysis Existing SCADA and management system integration requirements

System Design and Engineering

Custom busbar temperature monitoring system design including sensor selection, network architecture, alert configuration, and integration specifications. Engineering services ensure optimal system performance and compliance with electrical standards.

Design Services

Sensor Selection Optimal temperature sensor specifications for application requirements

Network Design Wireless network architecture and gateway placement for electrical environments

Alert Configuration Thermal threshold settings, escalation procedures, and notification rules

Dashboard Design Custom dashboard layouts for operational oversight and emergency response

Installation and Commissioning

Professional sensor installation with proper mounting, wireless verification, and system testing ensuring accurate thermal measurement from installation day forward. Installation services minimize operational disruptions while ensuring measurement quality.

- Sensor mounting on busbar surfaces and connection terminals

- Wireless communication testing and optimization in electrical environments

- System configuration and thermal threshold setting

- Dashboard setup and user account provisioning

- Calibration verification and thermal baseline documentation

- Staff training and operational handoff

Ongoing Support and Optimization

Comprehensive support services including system monitoring, alert management, performance analysis, and continuous thermal optimization.

- 24/7 system monitoring and emergency technical support

- Quarterly thermal performance review and optimization

- Sensor maintenance and recalibration services

- Software updates and feature enhancements

- Training for new staff and thermal management improvements

Professional Busbar Temperature Monitoring Commitment

3Phase Tech Services delivers comprehensive busbar temperature monitoring solutions providing accurate measurement and measurable operational improvements. Our electrical thermal specialists utilize proven DAVAS platform technology and industry best practices ensuring successful implementations with maximum return on investment.

Effective busbar thermal management requires precision measurement, reliable systems, and ongoing optimization to achieve reliability objectives and cost control. Our monitoring solutions provide comprehensive oversight while delivering immediate benefits and long-term optimization supporting electrical system resilience and operational excellence.

We continuously update monitoring capabilities, sensor technologies, and analytics platforms incorporating latest busbar thermal management advances and measurement best practices for optimal client results.

Ready to implement comprehensive busbar temperature monitoring for your electrical system? Contact our busbar thermal specialists to discuss your electrical system thermal monitoring requirements and develop a customized DAVAS solution that delivers reliable monitoring and measurable operational improvements.